2019 ATB

For each electricity generation technology in the ATB, this website provides:

- Capital expenditures (CAPEX): the definition of CAPEX used in the ATB and the historical trends, current estimates, and future projections of CAPEX used in the ATB

- Operations and maintenance (O&M) costs: the definition of O&M and the current estimates and future projections of O&M used in the ATB

- Capacity factor (CF): the definition of CF and the historical trends, current estimates, and future projections of CF used in the ATB

- Future cost and performance methods: an outline of the methodology used to make the projections of future cost and performance in the ATB for Constant, Mid, and Low technology cost cases

- Levelized cost of energy (LCOE): metric that combines CAPEX, O&M, CF, and projections for Constant, Mid, and Low technology cost cases for illustration of the combined effect of the primary cost and performance components and discussion of technology advances that yield future projections

- Financing assumptions: development of technology-specific interest rate on debt, return on equity, and debt-to-equity ratios and their impact on LCOE are documented in each technology section, where applicable, and summarized here.

Electricity generation technologies are selected on the left side of the screen, and the topics highlighted above can be selected using the drop-down menu at the top right of the screen.

Guidelines for using and interpreting ATB content and comparisons to other literature are provided. LCOE accounts for many variables important to determining the competitiveness of building and operating a specific technology (e.g., upfront capital costs, capacity factor, and cost of financing); however, it does not necessarily demonstrate which technology in a given place and time would provide the lowest cost option for the electricity grid. Such analysis is performed using electric sector models such as the Regional Energy Deployment Systems (ReEDS) model and corresponding analysis results such as the NREL Standard Scenarios.

The NREL Standard Scenarios, a companion product to the ATB, provides a suite of electric sector scenarios and associated assumptions, including technology cost and performance assumptions from the ATB.

ATB data sources and references are also provided for each technology. All dollar values are presented in 2017 U.S. dollars, unless noted otherwise.

Additional information is available here: About the 2019 ATB.

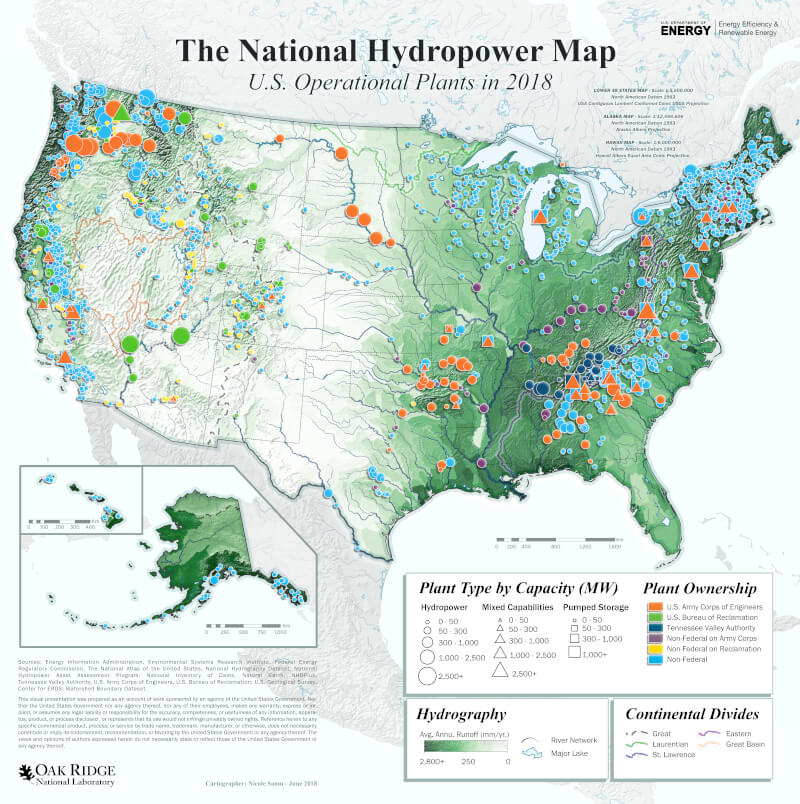

Hydropower

Renewable energy technical potential, as defined by Lopez et al. (2012) , represents the achievable energy generation of a particular technology given system performance, topographic limitations, and environmental and land-use constraints. The primary benefit of assessing technical potential is that it establishes an upper-boundary estimate of development potential. It is important to understand that there are multiple types of potential-resource, technical, economic, and market (see NREL: "Renewable Energy Technical Potential").

Note: Pumped-storage hydropower is considered a storage technology in the ATB and will be addressed in future years. It and other storage technologies are represented in Standard Scenarios Model Results from the ReEDS model, and battery storage technologies are shown in the associated portion of the ATB.

Representative Technology

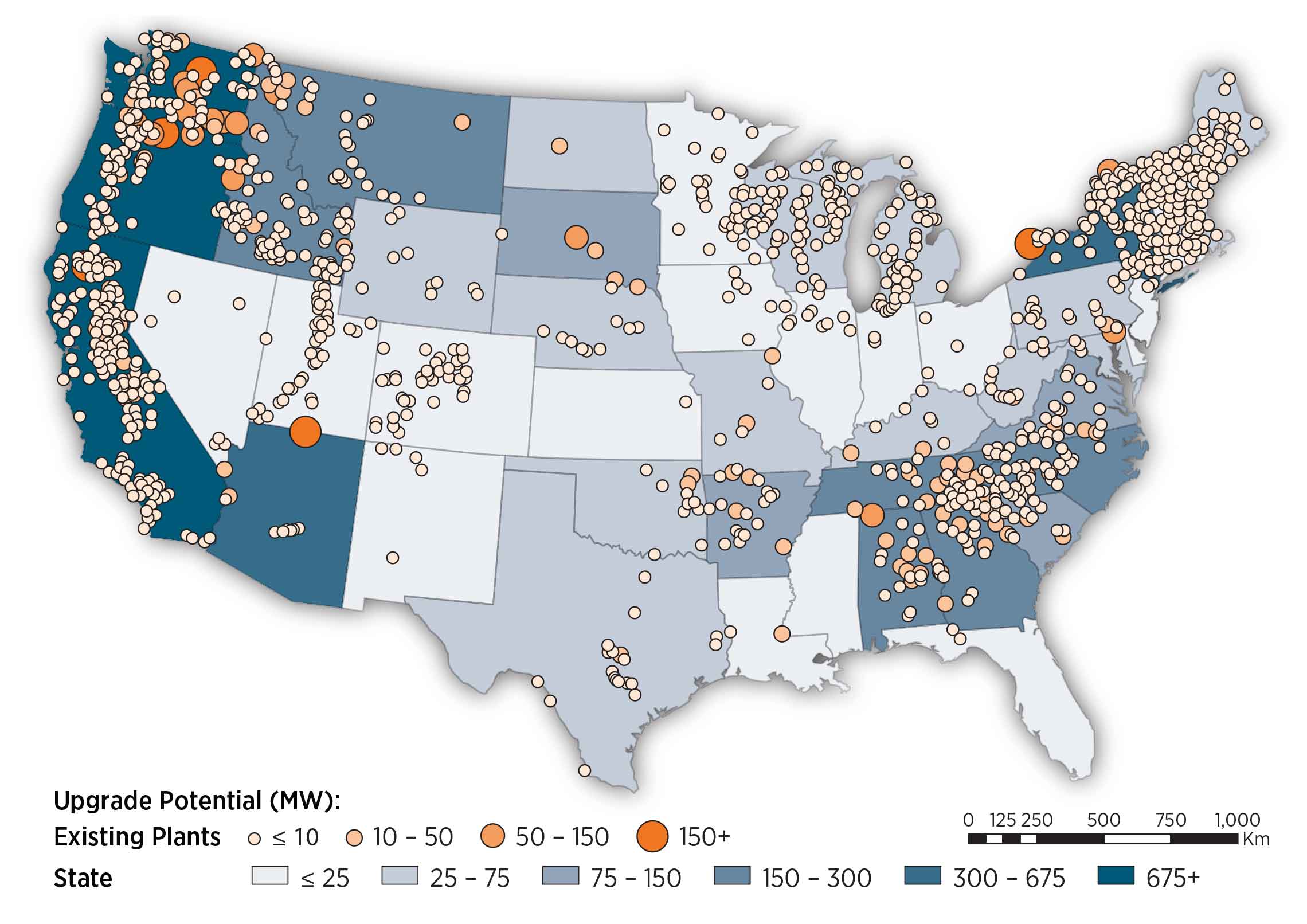

Hydropower technologies have produced electricity in the United States for over a century. Many of these infrastructure investments have potential to continue providing electricity in the future through upgrades of existing facilities (DOE, 2016) . At individual facilities, investments can be made to improve the efficiency of existing generating units through overhauls, generator rewinds, or turbine replacements. Such investments are known collectively as "upgrades," and they are reflected as increases to plant capacity. As plants reach a license renewal period, upgrades to existing facilities to increase capacity or energy output are typically considered. While the smallest projects in the United States can be as small as 10-100 kW, the bulk of upgrade potential is from large, multi-megawatt facilities.

Resource Potential

The estimated total upgrade potential of 6.9 GW/24 terawattt-hours (TWh) (at about 1,800 facilities) is based on generalizable information drawn from a series of case studies or owner-specific assessments (DOE, 2016) . Information available to inform the representation of improvements to the existing fleet includes:

- A systematic, full-fleet assessment of expansion potential at Reclamation projects performed under the Reclamation Hydropower Modernization Initiative (see U.S. Bureau of Reclamation, "Hydropower Resource Assessment at Existing Reclamation Facilities")

- Case study reports from the U.S. Army Corps of Engineers (Corps) performed under its Hydropower Modernization Initiative (MWH, Watson, & Harza, 2009)

- Case study reports combining assessments of upgrade and unit and plant optimization potential from the U.S. Department of Energy/Oak Ridge National Laboratory Hydropower Advancement Project.

Base Year and Future Year Projections Overview

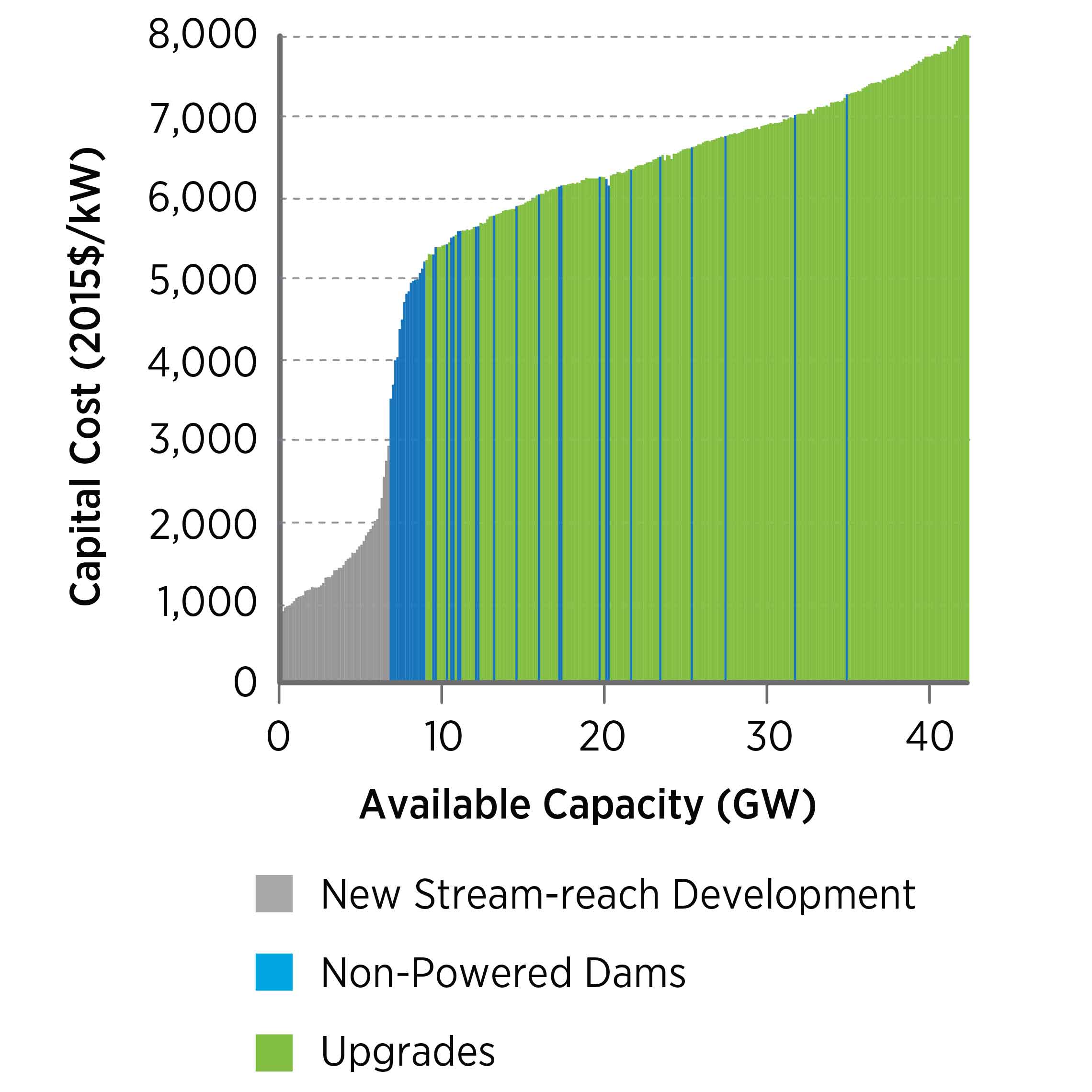

Upgrades are often among the lowest-cost new capacity resource, with the modeled costs for individual projects ranging from $800/kW to nearly $20,000/kW. This differential results from significant economies of scale from project size, wherein larger capacity plants are less expensive to upgrade on a dollar-per-kilowatt basis than smaller projects are. The average cost of the upgrade resource is approximately $1,500/kW.

CAPEX for each existing facility is based on direct estimates

The capacity factor is based on actual 10-year average energy production reported in EIA 923 forms. Some hydropower facilities lack flexibility and only produce electricity when river flows are adequate. Others with storage capabilities are operated to meet a balance between electric system, reservoir management, and environmental needs using their dispatch capability.

No future cost and performance projections for hydropower upgrades are assumed.

Upgrade cost and performance are not illustrated in this documentation of the ATB for the sake of simplicity.

Standard Scenarios Model Results

ATB CAPEX, O&M, and capacity factor assumptions for the Base Year and future projections through 2050 for Constant, Mid, and Low technology cost scenarios are used to develop the NREL Standard Scenarios using the ReEDS model. See ATB and Standard Scenarios.

Upgrade potential becomes available in the ReEDS model at the relicensing date, end of plant life (50 years), or both.

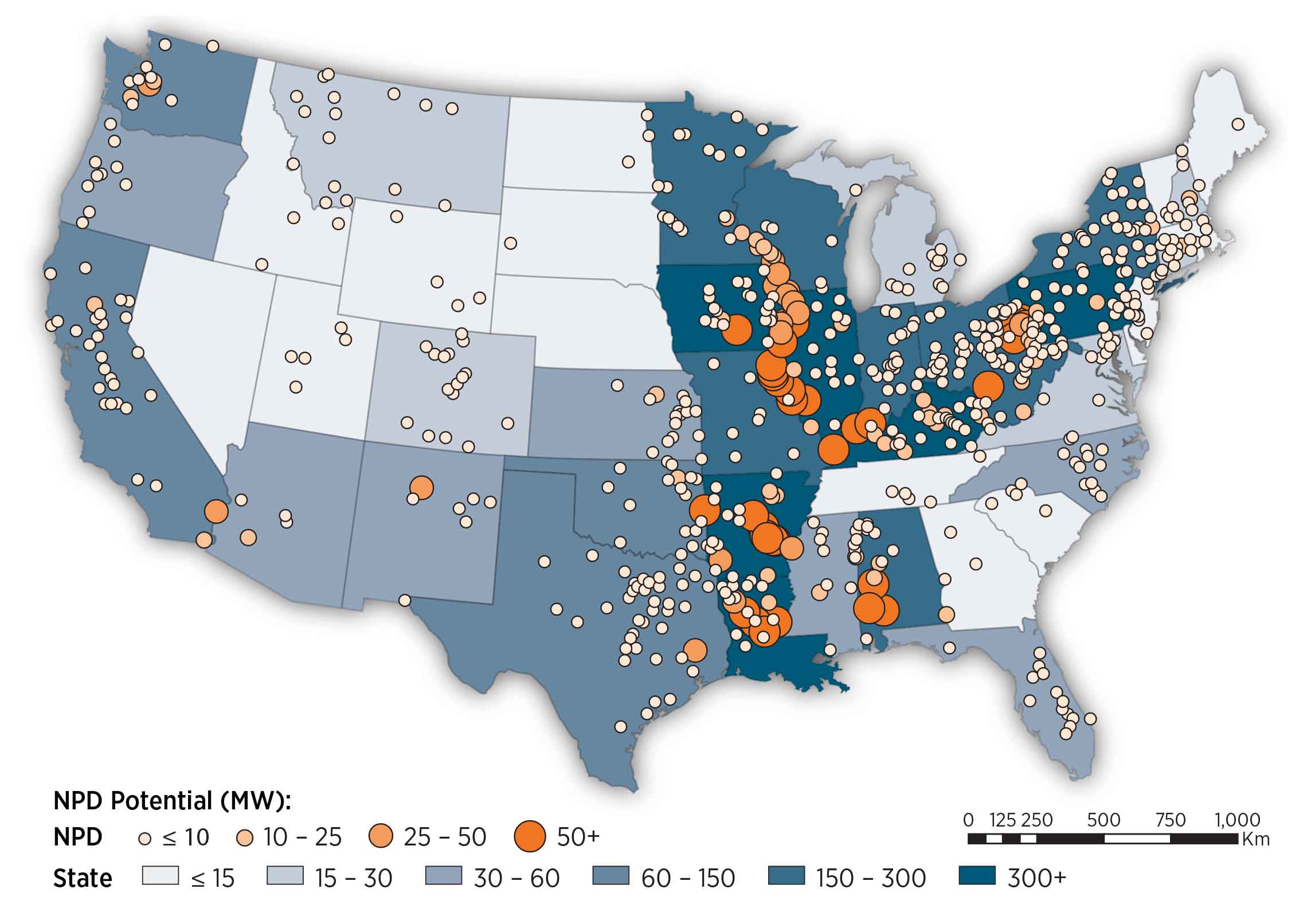

Representative Technology

Non-powered dams (NPD) are classified by energy potential in terms of head. Low head facilities have design heads below 20 m and typically exhibit the following characteristics (DOE, 2016) :

- 1 MW to 10 MW

- New/rehabilitated intake structure

- Little, if any, new penstock

- Axial-flow or Kaplan turbines (2-4 units)

- New powerhouse (indoor)

- New/rehabilitated tailrace

- Minimal new transmission (< 5 miles, if required)

- Capacity factor of 35% to 60%.

High head facilities have design heads above 20 m and typically exhibit the following characteristics (DOE, 2016) :

- 5 MW to 30 MW

- New/rehabilitated intake structure

- New penstock (typically < 500 feet of steel penstock, if required)

- Francis turbines (1-3 units)

- New powerhouse (indoor)

- New/rehabilitated tailrace

- Minimal new transmission line (up to 15 MW, if required)

- Capacity factor of 35% to 60%.

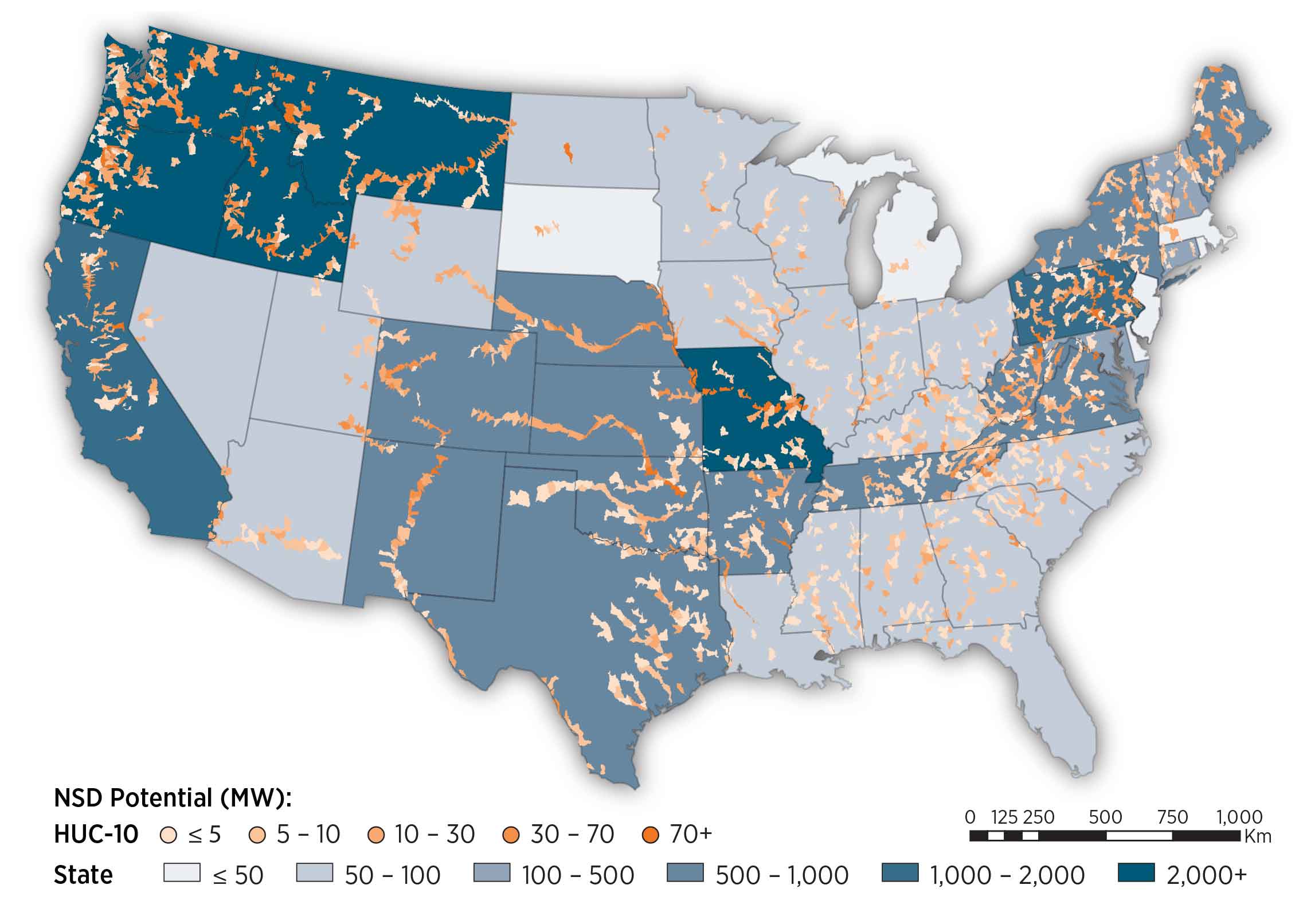

Resource Potential

Up to 12 GW of technical potential exists to add power to U.S. NPD. However, based on financial decisions in recent development activity, the economic potential of NPD may be approximately 5.6 GW at more than 54,000 dams in the contiguous United States. Most of this potential (5 GW or 90% of resource capacity) is associated with less than 700 dams. These resource considerations are discussed below:

According to the National

Inventory of Dams, more than 80,000 dams exist that do not produce

power. This data set was filtered to remove dams with erroneous flow

and geographic data and dams whose data could not be resolved to a

satisfactory level of detail

A new methodology for sizing potential hydropower facilities that was developed for the new-stream reach development resource (Kao et al., 2014) was applied to non-powered dams. This resource potential was estimated to be 5.6 GW at more than 54,000 dams. In the development of the Hydropower Vision, the NPD resource available to the ReEDS model was adjusted based on recent development activity and limited to only those projects with power potential of 500 kW or more. As the ATB uses the Hydropower Vision supply curves, this results in a final resource potential of 5 GW/29 TWh from 671 dams.

For each facility, a design capacity, average monthly flow rate over a 30-year period, and a design flow rate exceedance level of 30% are assumed. The exceedance level represents the fraction of time that the design flow is exceeded. This parameter can be varied and results in different capacity and energy generation for a given site. The value of 30% was chosen based on industry rules of thumb. The capacity factor for a given facility is determined by these design criteria.

Design capacity and flow rate dictate capacity and energy generation potential. All facilities are assumed sized for 30% exceedance of flow rate based on long-term, average monthly flow rates.

Base Year and Future Year Projections Overview

Site-specific CAPEX, O&M, and capacity factor estimates are made

for each site in the available resource potential. CAPEX and O&M

estimates are made based on statistical analysis of historical plant

data from 1980 to 2015

Projections developed for the Hydropower Vision study (DOE, 2016) using technological learning assumptions and bottom-up analysis of process and/or technology improvements provide a range of future cost outcomes. Three different projections were developed for scenario modeling as bounding levels:

- Constant Technology Cost Scenario: no change in CAPEX, O&M, or capacity factor from 2017 to 2050; consistent across all renewable energy technologies in the ATB

- Mid Technology Cost Scenario: incremental technology learning, consistent with Reference in Hydropower Vision (DOE, 2016); CAPEX reductions for new stream-reach development (NSD) only

- Low cost: gains that are achievable when pushing to the limits of potential new technologies, such as modularity (in both civil structures and power train design), advanced manufacturing techniques, and materials, consistent with Advanced Technology in Hydropower Vision (DOE, 2016); both CAPEX and O&M cost reductions implemented.

Standard Scenarios Model Results

ATB CAPEX, O&M, and capacity factor assumptions for the Base Year and future projections through 2050 for Constant, Mid, and Low technology cost scenarios are used to develop the NREL Standard Scenarios using the ReEDS model. See ATB and Standard Scenarios.

The ReEDS model includes a sensitivity scenario that restricts the resource potential to sites greater than 500 kW, consistent with the Hydropower Vision, which results in 5 GW/29 TWh at 671 dams.

Representative Technology

Greenfield or new stream-reach development (NSD) sites are defined as new hydropower developments along previously undeveloped waterways and typically exhibit the following characteristics (DOE, 2016) :

- 1 MW to 100 MW

- New diversion/intake structure

- New penstock

- Steel with length being head/terrain dependent

- Various turbine selections

- Impulse/Francis are common for recently completed projects

- New powerhouse (indoor)

- New tailrace

- New transmission line (up to 15 miles for new projects)

- 30% to 80% capacity factor.

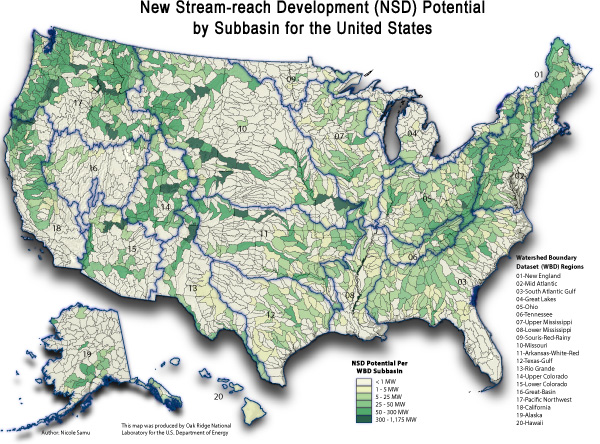

Resource Potential

The resource potential is estimated to be 53.2 GW/301 TWh at nearly 230,000 individual sites (Kao et al., 2014) after accounting for locations statutorily excluded from hydropower development such as national parks, wild and scenic rivers, and wilderness areas.

About 8,500 stream reaches were evaluated to assess resource potential (i.e., capacity) and energy generation potential (i.e., capacity factor). For each stream reach, a design capacity, average monthly flow rate over a 30-year period, and design flow rate exceedance level of 30% are assumed. The exceedance level represents the fraction of time that the design flow is exceeded. This parameter can be varied and results in different capacity and energy generation for a given site. The value of 30% was chosen based on industry rules of thumb. The capacity factor for a given facility is determined by these design criteria. Plant sizes range from kilowatt-scale to multi-megawatt scale (Kao et al., 2014) .

The resource assessment approach is designed to minimize the footprint of a hydropower facility by restricting inundation area to the Federal Emergency Management Agency (FEMA) 100-year floodplain.

New hydropower facilities are assumed to apply run-of-river operation strategies. Run-of-river operation means the flow rate into a reservoir is equal to the flow rate out of the facility. These facilities do not have dispatch capability.

Design capacity and flow rate dictate capacity and energy generation potential. All facilities are assumed sized for 30% exceedance of flow rate based on long-term, average monthly flow rates.

Base Year and Future Year Projections Overview

Site-specific CAPEX, O&M, and capacity factor estimates are made

for each site in the available resource potential. CAPEX and O&M

estimates are made based on statistical analysis of historical plant

data from 1980 to 2015

Projections developed for the Hydropower Vision study (DOE, 2016) using technological learning assumptions and bottom-up analysis of process and/or technology improvements provide a range of future cost outcomes. Three different projections were developed for scenario modeling as bounding levels:

- Constant Technology Cost Scenario: no change in CAPEX, O&M, or capacity factor from 2017 to 2050; consistent across all renewable energy technologies in the ATB

- Mid Technology Cost Scenario: incremental technology learning, consistent with Reference in Hydropower Vision (DOE, 2016); CAPEX reductions for NSD only

- Low Technology Cost Scenario: gains that are achievable

when pushing to the limits of potential new technologies, such as

modularity (in both civil structures and power train design), advanced

manufacturing techniques, and materials, consistent with Advanced

Technology in Hydropower Vision

(DOE, 2016) ; both CAPEX and O&M cost reductions implemented.

Standard Scenarios Model Results

ATB CAPEX, O&M, and capacity factor assumptions for the Base Year and future projections through 2050 for Constant, Mid, and Low technology cost scenarios are used to develop the NREL Standard Scenarios using the ReEDS model. See ATB and Standard Scenarios.

The ReEDS model includes a sensitivity scenario that restricts the resource potential to sites greater than 1 MW, which results in 30.1 GW/176 TWh on nearly 8,000 reaches.

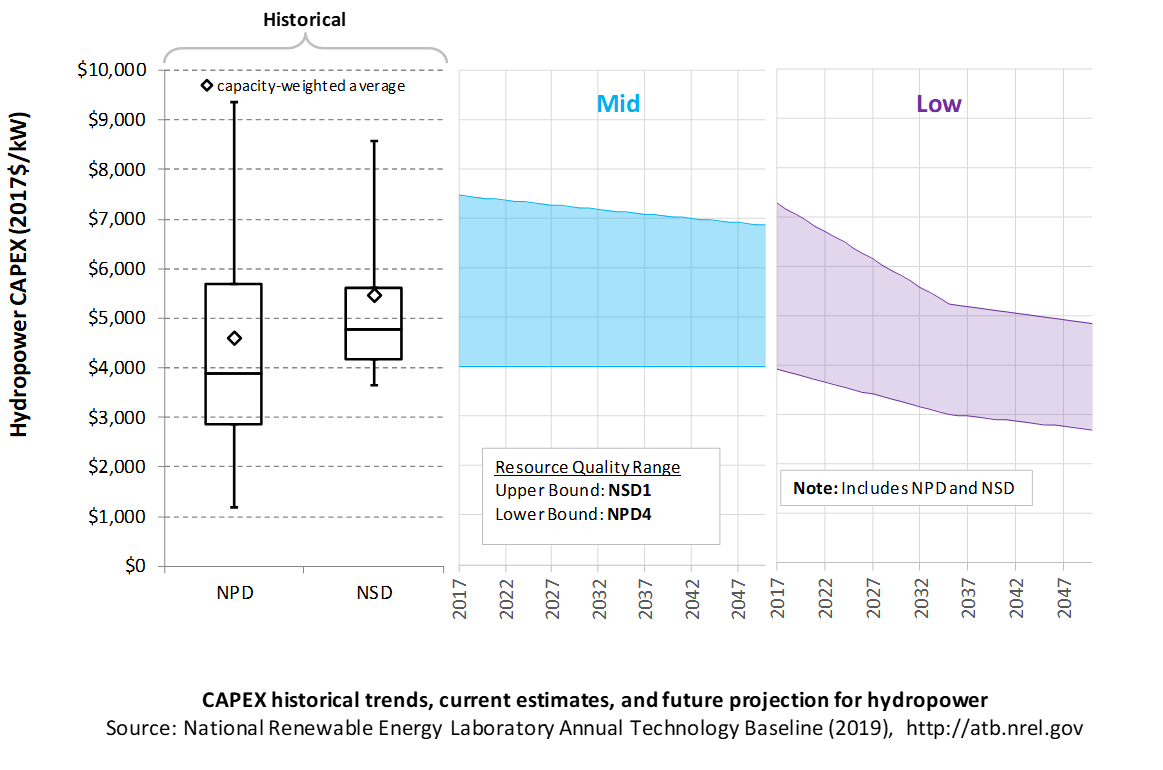

Capital Expenditures (CAPEX): Historical Trends, Current Estimates, and Future Projections

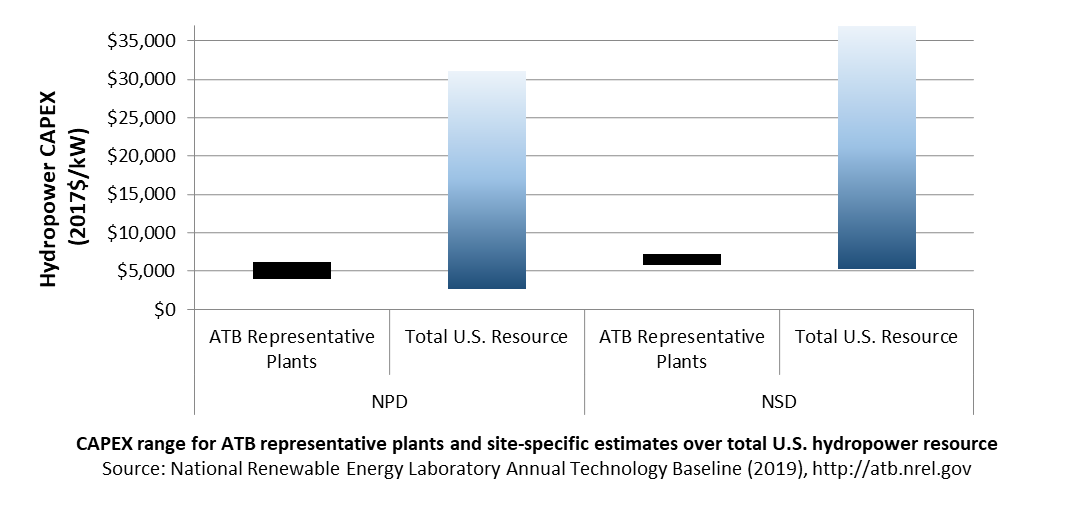

Capital expenditures (CAPEX) are expenditures required to achieve commercial operation in a given year. These expenditures include the hydropower generation plant, the balance of system (e.g., site preparation, installation, and electrical infrastructure), and financial costs (e.g., development costs, onsite electrical equipment, and interest during construction) and are detailed in CAPEX Definition. In the ATB, CAPEX reflects typical plants and does not include differences in regional costs associated with labor, materials, taxes, or system requirements. The related Standard Scenarios product uses regional CAPEX adjustments. The range of CAPEX demonstrates variation with resource in the contiguous United States.

The following figure shows the Base Year estimate and future year projections for CAPEX costs. Mid and Low technology cost scenarios are shown. Historical data from actual and proposed non-powered dam (NPD) and new stream-reach development (NSD) plants installed in the United States from 1981 to 2014 are shown for comparison to the ATB Base Year. The estimate for a given year represents CAPEX of a new plant that reaches commercial operation in that year.

Recent Trends

Actual and proposed NPD and NSD CAPEX from 1981 to 2014

The higher-cost ATB sites generally reflect small-capacity, low head sites that are not comparable to the historical data sample's generally larger-capacity and higher head facilities. These characteristics lead to higher ATB Base Year CAPEX estimates than past data suggest. For example, the NSD projects that became commercially operational in this period are dominated by a few high head projects in the mountains of the Pacific Northwest or Alaska.

The Base Year estimates of CAPEX for NPDs in the ATB range from $3,800/kW to $6,000/kW. These estimates reflect facilities with 3 feet of head to more than 60 feet of head and from 0.5 MW to more than 30 MW of capacity. In general, the higher-cost sites reflect much smaller-capacity (< 10 MW), lower head (< 30 ft.) sites that have fewer analogues in the historical data, but these characteristics result in higher CAPEX.

The Base Year estimates of CAPEX for NSD range from $5,500/kW to $7,900/kW. The estimates reflect potential sites with 3 feet of head to more than 60 feet head and from 1 MW to more than 30 MW of capacity. In general, NSD potential represents smaller-capacity facilities with lower head than most historical data represent. These characteristics lead to higher CAPEX estimates than past data suggest, as many of the larger, higher head sites in the United States have been previously developed.

Base Year Estimates

For illustration in the ATB, all potential NPD and NSD sites were first binned by both head and capacity. Analysis of these bins provided groupings that represent the most realistic conditions for future hydropower deployment. The design values of these four reference NPD and four reference NSD plants are shown below. The full range of resource and design characteristics is summarized in the ATB data spreadsheet.

Representative Hydropower Plants

| Resource Characteristics Ranges | Weighted Average Values | Calculated Plant Values | |||||

| Plants | Head (feet) | Capacity (MW) | Head (feet) | Capacity (MW) | Capacity Factor | ICC (2014$/kW) | O&M (2014$/kW) |

| NPD 1 | 3-30 | 0.5-10 | 15.4 | 4.8 | 0.62 | 5,969.33 | 111.73 |

| NPD 2 | 3-30 | 10+ | 15.9 | 82.2 | 0.64 | 5,433.24 | 30.74 |

| NPD 3 | 30+ | 0.5-10 | 89.6 | 4.2 | 0.60 | 3,997.79 | 118.67 |

| NPD 4 | 30+ | 10+ | 81.3 | 44.7 | 0.60 | 3,769.22 | 40.54 |

| NSD 1 | 3-30 | 1-10 | 15.7 | 3.7 | 0.66 | 7,034.81 | 125.01 |

| NSD 2 | 3-30 | 10+ | 19.6 | 44.1 | 0.66 | 6,280.15 | 40.76 |

| NSD 3 | 30+ | 1-10 | 46.8 | 4.3 | 0.62 | 6,151.05 | 117.61 |

| NSD 4 | 30+ | 10+ | 45.3 | 94.0 | 0.66 | 5,537.34 | 28.93 |

The reference plants shown above were developed using the average characteristics (weighted by capacity) of the resource plants within each set of ranges. For example, NPD 1 is constructed from the capacity-weighted average values of NPD sites with 3-30 feet of head and 0.5-10 MW of capacity.

The weighted-average values were used as input to the cost formulas

CAPEX for each plant is based on statistical analysis of historical

plant data from 1980 to 2015 as a function of key design parameters,

plant capacity, and hydraulic head

and

Where P is capacity in megawatts, and H is head in feet. The first term represents the initial capital costs, while the second represents licensing.

Future Projections

Projections developed for the Hydropower Vision study (DOE, 2016) using technological learning assumptions and bottom-up analysis of process and/or technology improvements provide a range of future cost outcomes. Three different CAPEX projections were developed for scenario modeling as bounding levels:

- Constant Technology Cost Scenario:

- NPD and NSD CAPEX unchanged from the Base Year; consistent across all renewable energy technologies in the ATB

- Mid Technology Cost Scenario: consistent with the Reference case in Hydropower Vision:

- NSD CAPEX reduced 5% in 2035 and 8.6% in 2050

- NPD CAPEX unchanged from the Base Year

- Low Technology Cost Scenario: consistent with the Advanced Technology case in Hydropower Vision:

- Low head NPD/All NSD CAPEX reduced 30% in 2035 and 35.3% in 2050. Low Head NPD is NPD-1 and NPD-2

- High head NPD CAPEX reduced 25% in 2035 and 32.7% in 2050; High Head NPD is NPD-3 and NPD-4

A detailed description of the methodology for developing future year projections is found in Projections Methodology.

Technology innovations that could impact future O&M costs are summarized in LCOE Projections.

Standard Scenarios Model Results

ATB CAPEX, O&M, and capacity factor assumptions for the Base Year and future projections through 2050 for Constant, Mid, and Low technology cost scenarios are used to develop the NREL Standard Scenarios using the ReEDS model. See ATB and Standard Scenarios.

The ReEDS model uses resource/cost supply curves representing estimates at each individual facility (~700 NPD and ~8,000 NSD).

The ReEDS model represents cost and performance for NPD and NSD potential in 5 bins for each of 134 geographic regions, which results in CAPEX ranges of $2,750/kW-$9,000/kW for NPD resource and $5,200/kW-$15,600/kW for NSD.

CAPEX Definition

Capital expenditures (CAPEX) are expenditures required to achieve commercial operation in a given year.

For the ATB, and based on (EIA, 2016) and the System Cost Breakdown Structure described by (O'Connor, Zhang, DeNeale, Chalise, & Centurion, 2015), the hydropower plant envelope is defined to include:

- Hydropower generation plant

- Civil works, such as site preparation, dams and reservoirs, water conveyances, and powerhouse structures

- Equipment, such as the powertrain and ancillary plant electrical and mechanical systems

- Balance of system (BOS)

- Installation and O&M infrastructure

- Electrical infrastructure, such as transformers, switchgear, and electrical system connecting turbines to each other and to the control center

- Project indirect costs, including costs related to environmental mitigation and regulatory compliance, engineering, distributable labor and materials, construction management start up and commissioning, and contractor overhead costs, fees, and profit

- Financial costs

- Owners' costs, such as development costs, preliminary feasibility and engineering studies, environmental studies and permitting, legal fees, insurance costs, and property taxes during construction

- Electrical interconnection and onsite electrical equipment (e.g., switchyard), a nominal-distance spur line (< 1 mile), and necessary upgrades at a transmission substation; distance-based spur line cost (GCC) not included in the ATB

- Interest during construction estimated based on three-year duration accumulated 10%/10%/80% at half-year intervals and an 8% interest rate (ConFinFactor).

CAPEX can be determined for a plant in a specific geographic location as follows:

Regional cost variations and geographically specific grid connection costs are not included in the ATB (CapRegMult = 1; GCC = 0). In the ATB, the input value is overnight capital cost (OCC) and details to calculate interest during construction (ConFinFactor).

In the ATB, CAPEX is shown for four representative non-powered dam plants and four representative new stream-reach development plants. CAPEX estimates for all identified hydropower potential (~700 NPD and ~8,000 NSD) results in a CAPEX range that is much broader than that shown in the ATB. It is unlikely that all the resource potential will be developed due to the very high costs for some sites. Regional cost effects and distance-based spur line costs are not estimated.

Standard Scenarios Model Results

ATB CAPEX, O&M, and capacity factor assumptions for the Base Year and future projections through 2050 for Constant, Mid, and Low technology cost scenarios are used to develop the NREL Standard Scenarios using the ReEDS model. See ATB and Standard Scenarios.

CAPEX in the ATB does not represent regional variants (CapRegMult) associated with labor rates, material costs, etc., and neither does the ReEDS model.

CAPEX in the ATB does not include geographically determined spur line (GCC) from plant to transmission grid, and neither does the ReEDS model.

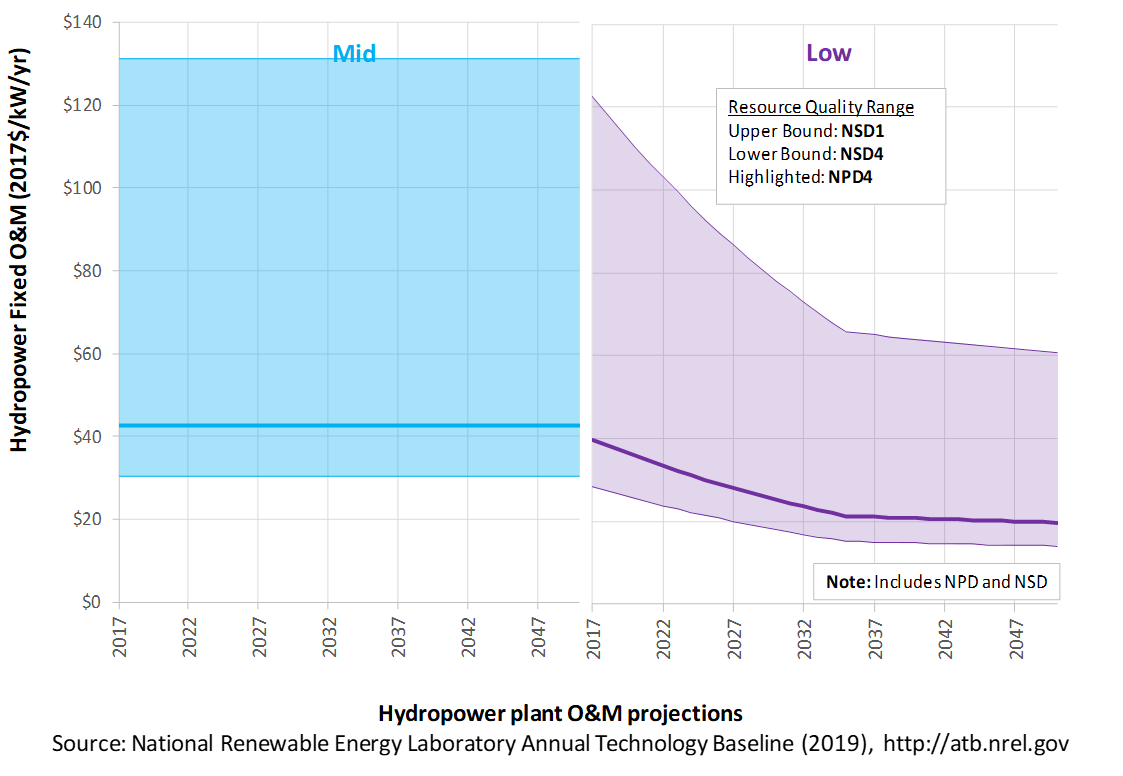

Operation and Maintenance (O&M) Costs

Operations and maintenance (O&M) costs represent average annual fixed expenditures (and depend on rated capacity) required to operate and maintain a hydropower plant over its lifetime, including:

- Insurance, taxes, land lease payments, and other fixed costs

- Present value and annualized large component overhaul or replacement costs over technical life (e.g., rewind stator, patch cavitation damage, and replace bearings)

- Scheduled and unscheduled maintenance of hydropower plant components, including turbines, generators, etc. over the technical lifetime of the plant.

The following figure shows the Base Year estimate and future year projections for fixed O&M (FOM) costs. Mid and Low technology cost scenarios are shown. The estimate for a given year represents annual average FOM costs expected over the technical lifetime of a new plant that reaches commercial operation in that year.

Base Year Estimates

A statistical analysis of long-term plant operation costs from Federal Energy Regulatory Commission Form-1 resulted in a relationship between annual, FOM costs, and plant capacity. Values were updated to 2017$.

Future Year Projections

Projections developed for the Hydropower Vision study (DOE, 2016) using technological learning assumptions and bottom-up analysis of process and/or technology improvements provide a range of future cost outcomes. Three different O&M projections were developed for scenario modeling as bounding levels:

- Constant Technology Cost Scenario: FOM costs unchanged from the Base Year to 2050; consistent with all ATB technologies

- Mid Technology Cost Scenario: FOM costs for both NPD and NSD plants are unchanged from 2017 to 2050; consistent with the Reference case in Hydropower Vision

- Low Technology Cost Scenario: FOM costs for both NPD and NSD plants are reduced by 50% in 2035 and 54% in 2050, consistent with the Advanced Technology case in Hydropower Vision.

A detailed description of the methodology for developing future year projections is found in Projections Methodology.

Technology innovations that could impact future O&M costs are summarized in LCOE Projections.

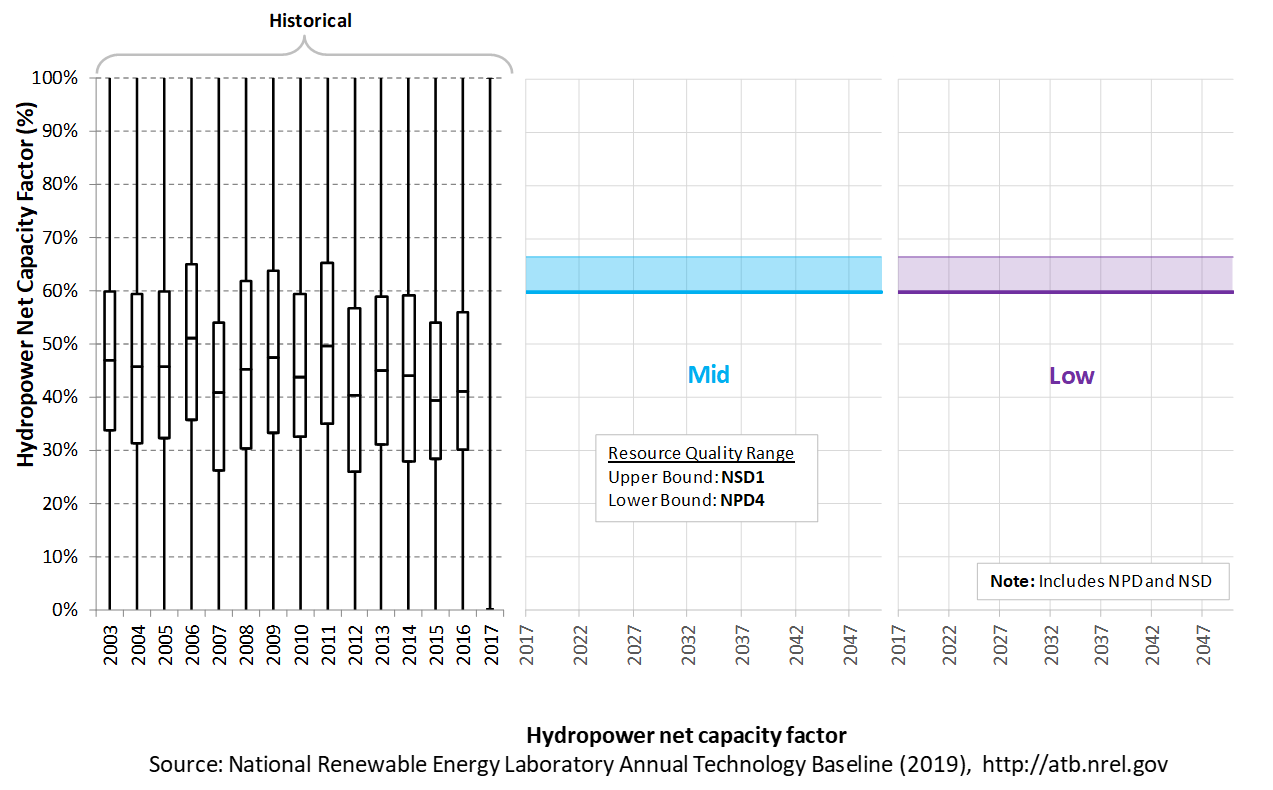

Capacity Factor: Expected Annual Average Energy Production Over Lifetime

The capacity factor represents the expected annual average energy production divided by the annual energy production, assuming the plant operates at rated capacity for every hour of the year. It is intended to represent a long-term average over the lifetime of the plant. It does not represent interannual variation in energy production. Future year estimates represent the estimated annual average capacity factor over the technical lifetime of a new plant installed in a given year.

The capacity factor is influenced by site hydrology, design factors (e.g., exceedance level), and operation characteristics (e.g., dispatch or run-of-river). Capacity factors for all potential NPD sites and NSDs are estimated based on design criteria, long-term monthly flow rate records, and run-of-river operation.

The following figure shows a range of capacity factors based on variation in the resource for hydropower plants in the contiguous United States. Historical data from run-of-river hydropower plants operating in the United States from 2003 through 2012 are shown for comparison with the Base Year estimates. The range of the Base Year estimates illustrates the effect of resource variation. Future projections for the Constant, Mid, and Low technology cost scenarios are unchanged from the Base Year. Technology improvements are focused on CAPEX and O&M cost elements.

Recent Trends

Actual energy production from about 200 run-of-river plants operating in the United States from 2003 to 2012 (EIA, 2016) is shown in box-and-whiskers format for comparison with current estimates and future projections. This sample includes some very old plants that may have lower availability and efficiency. It also includes plants that have been relicensed and may no longer be optimally designed for current operating regime (e.g., a peaking unit now operating as run-of-river). This contributes to the broad range, particularly on the low end.

Interannual variation of hydropower plant output for run-of-river plants may be significant due to hydrological changes such as drought. This impact may be exacerbated by climate change over the long term.

Current and future estimates for new hydropower plants are within the range of observed plant performance. These potential hydropower plants would be designed for specific site conditions, which would indicate operation toward the high end of the range.

Base Year Estimates

For illustration in the ATB, all potential NPD and NSD sites are represented with four reference plants, each as described below.

Representative Hydropower Plants

| Resource Characteristics Ranges | Weighted Average Values | Calculated Plant Values | |||||

| Plants | Head (feet) | Capacity (MW) | Head (feet) | Capacity (MW) | Capacity Factor | ICC (2014$/kW) | O&M (2014$/kW) |

| NPD 1 | 3-30 | 0.5-10 | 15.4 | 4.8 | 0.62 | 5,969.33 | 111.73 |

| NPD 2 | 3-30 | 10 + | 15.9 | 82.2 | 0.64 | 5,433.24 | 30.74 |

| NPD 3 | 30 + | 0.5-10 | 89.6 | 4.2 | 0.60 | 3,997.79 | 118.67 |

| NPD 4 | 30 + | 10 + | 81.3 | 44.7 | 0.60 | 3,769.22 | 40.54 |

| NSD 1 | 3-30 | 1-10 | 15.7 | 3.7 | 0.66 | 7,034.81 | 125.01 |

| NSD 2 | 3-30 | 10 + | 19.6 | 44.1 | 0.66 | 6,280.15 | 40.76 |

| NSD 3 | 30 + | 1-10 | 46.8 | 4.3 | 0.62 | 6,151.05 | 117.61 |

| NSD 4 | 30 + | 10 + | 45.3 | 94.0 | 0.66 | 5,537.34 | 28.93 |

Future Year Projections

The capacity factor remains unchanged from the Base Year through 2050. Technology improvements are focused on CAPEX and O&M costs.

Standard Scenarios Model Results

ATB CAPEX, O&M, and capacity factor assumptions for the Base Year and future projections through 2050 for Constant, Mid, and Low technology cost scenarios are used to develop the NREL Standard Scenarios using the ReEDS model. See ATB and Standard Scenarios.

The ReEDS model uses resource/cost supply curves representing estimates at each individual facility (~700 NPD and ~8,000 NSD).

The ReEDS model represents cost and performance for NPD and NSD potential in 5 bins for each of 134 geographic regions, which results in capacity factor ranges of 38%-80% for the NPD resources and 53%-81% for NSD.

Existing hydropower facilities in the ReEDS model provide dispatch capability such that their annual energy production is determined by the electric system needs by dispatching generators to accommodate diurnal and seasonal load variations and output from variable generation sources (e.g., wind and solar PV).

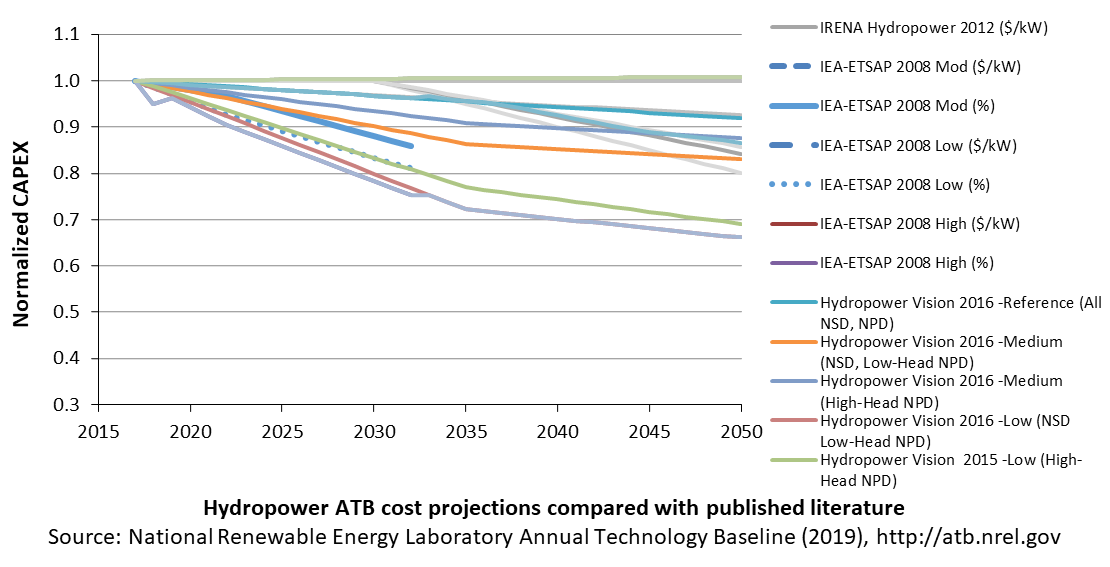

Plant Cost and Performance Projections Methodology

Projections developed for the Hydropower Vision study (DOE, 2016) using technological learning assumptions and bottom-up analysis of process and/or technology improvements provide a range of future cost outcomes. Three different projections were developed for scenario modeling as bounding levels:

- Constant Technology Cost Scenario: no change in CAPEX or OPEX from 2017 to 2050; consistent across all renewable energy technologies in the ATB

- Mid Technology Cost Scenario: incremental learning, consistent with Reference in the Hydropower Vision study (DOE, 2016); CAPEX reductions for NSD only

- Low Technology Cost Scenario: gains that are achievable when pushing to the limits of potential new technologies, such as modularity (in both civil structures and power train design), advanced manufacturing techniques, and materials, consistent with Advanced Technology in Hydropower Vision (DOE, 2016); both CAPEX and O&M cost reductions implemented.

A range of literature projections is shown for comparison. The Mid and Low cost cases use a mix of inputs based on EIA technological learning assumptions, input from a technical team of Oak Ridge National Laboratory researchers, and the experience of expert hydropower consultants. Estimated 2035 cost levels are intended to provide order-of-magnitude cost reductions deemed to be at least conceptually possible, and they are meant to stimulate a broader discussion with the hydropower industry and its stakeholders that will be necessary to the future of cost reduction in the industry. Cost projections were derived independently for NPD and NSD technologies.

For context, ATB cost projections are compared to the literature, which represents 7 independent published studies and 11 cost projection scenarios within these studies. Cost reduction literature for hydropower is limited with several studies projecting no change through 2050. It is unclear whether (1) this represents a deliberate estimate of no future change in cost or (2) no estimate has been made.

Hydropower investment costs are very site specific and vary with type of technology. Literature was reviewed to attempt to isolate perceived CAPEX reduction for resources of similar characteristics over time (e.g., estimated cost to develop the same site in 2015, 2030, and 2050 based on different technology, installation, and other technical aspects). Some studies reflect increasing CAPEX over time. These studies were excluded from the ATB based on the interpretation that rising costs reflect a transition to less attractive sites as the better sites are used earlier.

Literature estimates generally reflect hydropower facilities of sizes similar to those represented in U.S. resource potential (i.e., they exclude estimates for very large facilities). Due to limited sample size, all projections are analyzed together without distinction between types of technology. Note that although declines are shown on a percentage basis, the reduction is likely to vary with initial capital cost. Large reductions for moderately expensive sites may not scale to more expensive sites or to less expensive sites. Projections derived for the Hydropower Vision study for different technologies (Low Head NPD, High Head NPD, and NSD) address this simplification somewhat.

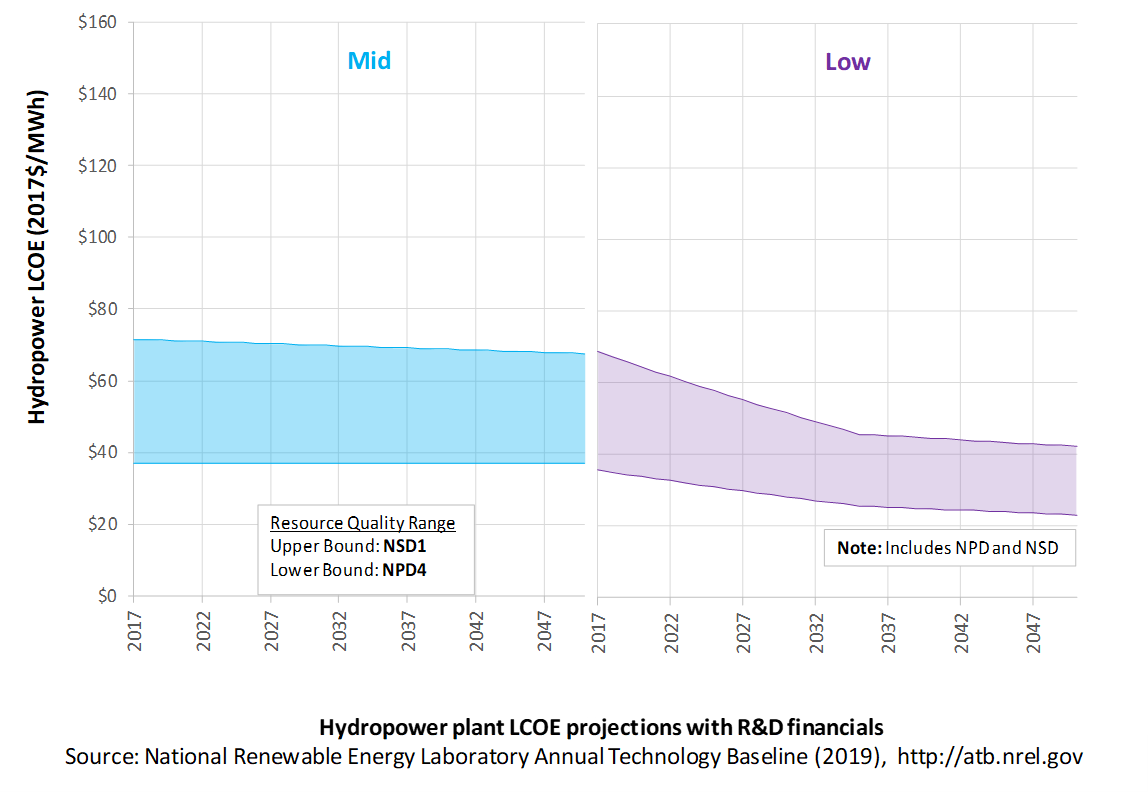

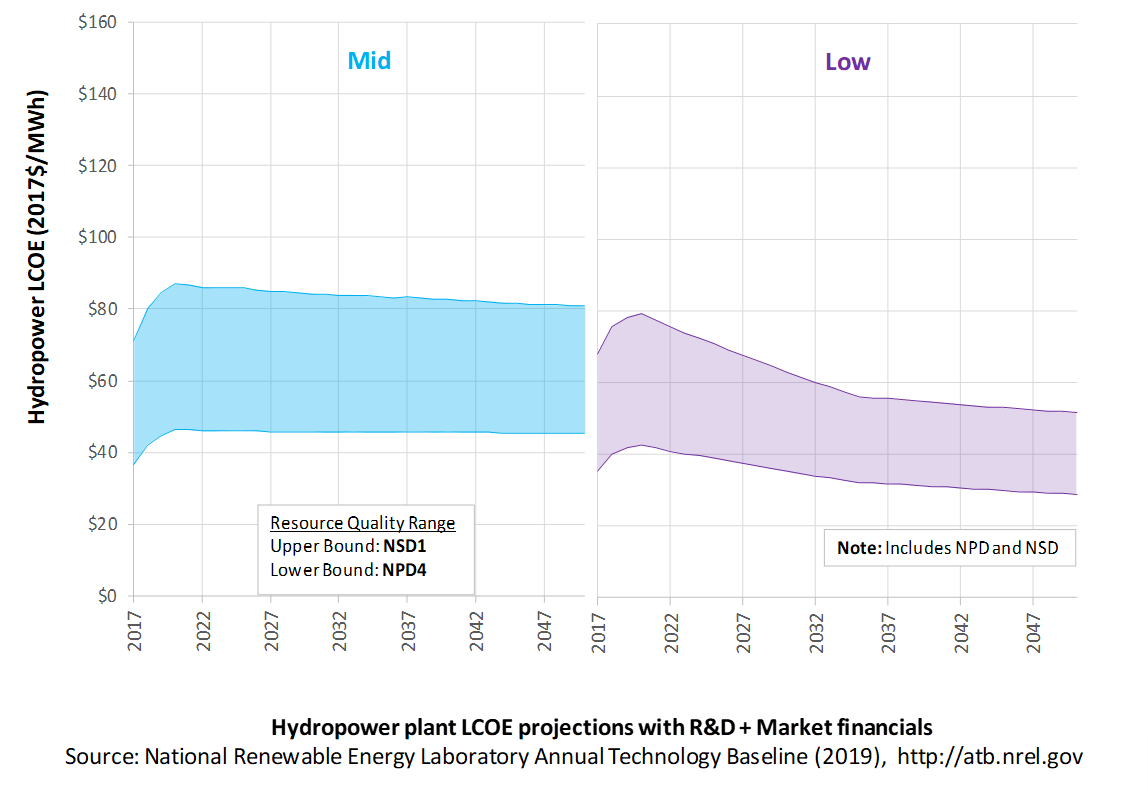

Levelized Cost of Energy (LCOE) Projections

Levelized cost of energy (LCOE) is a summary metric that combines the primary technology cost and performance parameters: CAPEX, O&M, and capacity factor. It is included in the ATB for illustrative purposes. The ATB focuses on defining the primary cost and performance parameters for use in electric sector modeling or other analysis where more sophisticated comparisons among technologies are made. The LCOE accounts for the energy component of electric system planning and operation. The LCOE uses an annual average capacity factor when spreading costs over the anticipated energy generation. This annual capacity factor ignores specific operating behavior such as ramping, start-up, and shutdown that could be relevant for more detailed evaluations of generator cost and value. Electricity generation technologies have different capabilities to provide such services. For example, wind and PV are primarily energy service providers, while the other electricity generation technologies such as hydropower can provide capacity and flexibility services in addition to energy. These capacity and flexibility services are difficult to value and depend strongly on the system in which a new generation plant is introduced. These services are represented in electric sector models such as the ReEDS model and corresponding analysis results such as the Standard Scenarios.

The following three figures illustrate LCOE, which includes the combined impact of CAPEX, O&M, and capacity factor projections for hydropower across the range of resources present in the contiguous United States. For the purposes of the ATB, the costs associated with technology and project risk in the U.S. market are represented in the financing costs but not in the upfront capital costs (e.g., developer fees and contingencies). An individual technology may receive more favorable financing terms outside the United States, due to less technology and project risk, caused by more project development experience (e.g., offshore wind in Europe) or more government or market guarantees. The R&D Only LCOE sensitivity cases present the range of LCOE based on financial conditions that are held constant over time unless R&D affects them, and they reflect different levels of technology risk. This case excludes effects of tax reform, tax credits, and changing interest rates over time. The R&D + Market LCOE case adds to these financial assumptions: (1) the changes over time consistent with projections in the Annual Energy Outlook and (2) the effects of tax reform and tax credits. The representative plant characteristics in the ATB that best align with those of recently installed or anticipated near-term hydropower plants are associated with NPD 4. Data for all the resource categories can be found in the ATB Data spreadsheet; for simplicity, not all resource categories are shown in the figures.

R&D Only | R&D + Market

The methodology for representing the CAPEX, O&M, and capacity factor assumptions behind each pathway is discussed in Projections Methodology. In general, the degree of adoption of technology innovation distinguishes the Constant, Mid, and Low technology cost scenarios. These projections represent trends that reduce CAPEX and improve performance. Development of these scenarios involves technology-specific application of the following general definitions:

- Constant Technology: Base Year (or near-term estimates of projects under construction) equivalent through 2050 maintains current relative technology cost differences

- Mid Technology Cost Scenario: Technology advances through continued industry growth, public and private R&D investments, and market conditions relative to current levels that may be characterized as "likely" or "not surprising"

- Low Technology Cost Scenario: Technology advances that may occur with breakthroughs, increased public and private R&D investments, and/or other market conditions that lead to cost and performance levels that may be characterized as the " limit of surprise" but not necessarily the absolute low bound.

To estimate LCOE, assumptions about the cost of capital to finance electricity generation projects are required, and the LCOE calculations are sensitive to these financial assumptions. Two project finance structures are used within the ATB:

- R&D Only Financial Assumptions: This sensitivity case allows technology-specific changes to debt interest rates, return on equity rates, and debt fraction to reflect effects of R&D on technological risk perception, but it holds background rates constant at 2017 values from AEO2019 (EIA, 2019) and excludes effects of tax reform and tax credits.

- R&D Only + Market Financial Assumptions: This sensitivity case retains the technology-specific changes to debt interest, return on equity rates, and debt fraction from the R&D Only case and adds in the variation over time consistent with AEO2019 (EIA, 2019), as well as effects of tax reform and tax credits. For a detailed discussion of these assumptions, see Project Finance Impact on LCOE.

A constant cost recovery period – over which the initial capital investment is recovered – of 30 years is assumed for all technologies throughout this website, and can be varied in the ATB data spreadsheet.

The equations and variables used to estimate LCOE are defined on the Equations and Variables page. For illustration of the impact of changing financial structures such as WACC, see Project Finance Impact on LCOE. For LCOE estimates for the Constant, Mid, and Low technology cost scenarios for all technologies, see 2019 ATB Cost and Performance Summary.

In general, differences among the technology cost cases reflect different levels of adoption of innovations. Reductions in technology costs reflect the cost reduction opportunities that are listed below.

- Widespread implementation of value engineering and design/construction best practices

- Modular "drop-in" systems that minimize civil works and maximize ease of manufacture reduce both capital investment and O&M expenditures

- Use of alternative materials in place of steel for water diversion (e.g., penstocks)

- Implementation of standardized "smart" automation and remote monitoring systems to optimize scheduling of maintenance

- Research and development on environmentally enhanced turbines to improve performance of the existing hydropower fleet

- Efficient, certain, permitting, licensing, and approval procedures.

The Hydropower Vision study (DOE, 2016) includes road map actions that result in lower-cost technology.

Battery Storage

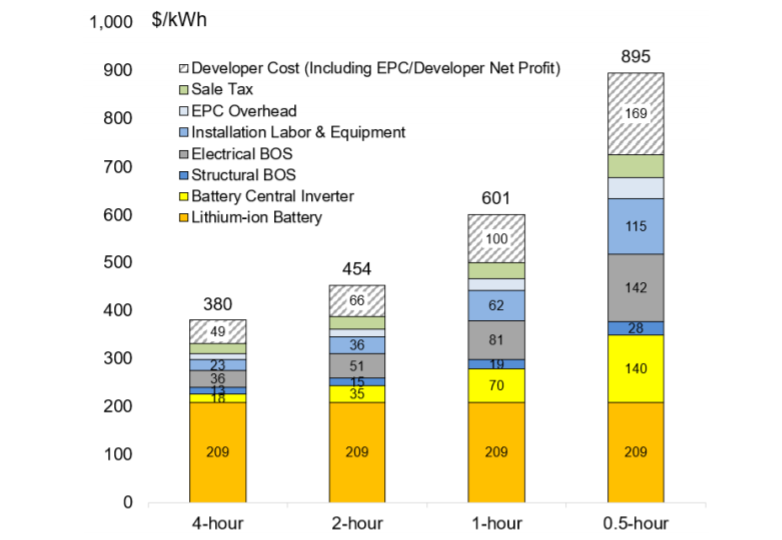

Energy storage technologies are important to document in the ATB because of their potential role in enhancing grid flexibility, especially under scenarios of high penetration of variable renewable technologies. CSP with TES and Hydropower both include storage capabilities, and a variety of other storage technologies could enhance the flexibility of the electrical grid. This section documents assumptions about only one of them: 4-hour, utility-scale, lithium-ion battery storage. NREL has completed recent analysis on ranges of costs related to other battery sizes (Fu, Remo, & Margolis, 2018) with relative costs represented in Figure ES-1 of the report (included below) which looked at 4-hour to 0.5 hour battery duration of utility scale plants.

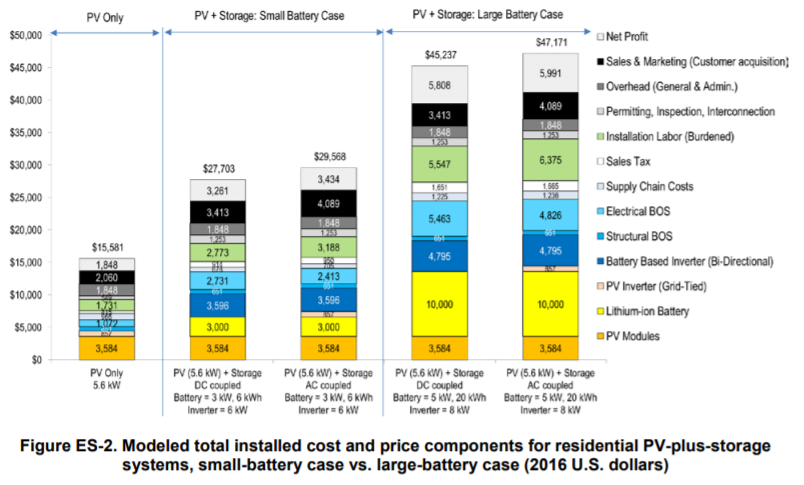

The ATB does not currently have costs for distributed battery storage-either for residential nor commercial applications behind the meter nor for a micro-grid or off-grid application. NREL has completed prior work on residential battery plus solar PV system analysis (Ardani et al., 2017) resulting in a range of costs of PV+battery systems as shown in the figure below. Note these costs are for 2016 and published in 2017, so we anticipate battery costs to be significantly lower currently.

Base Year and Future Year Projections Overview

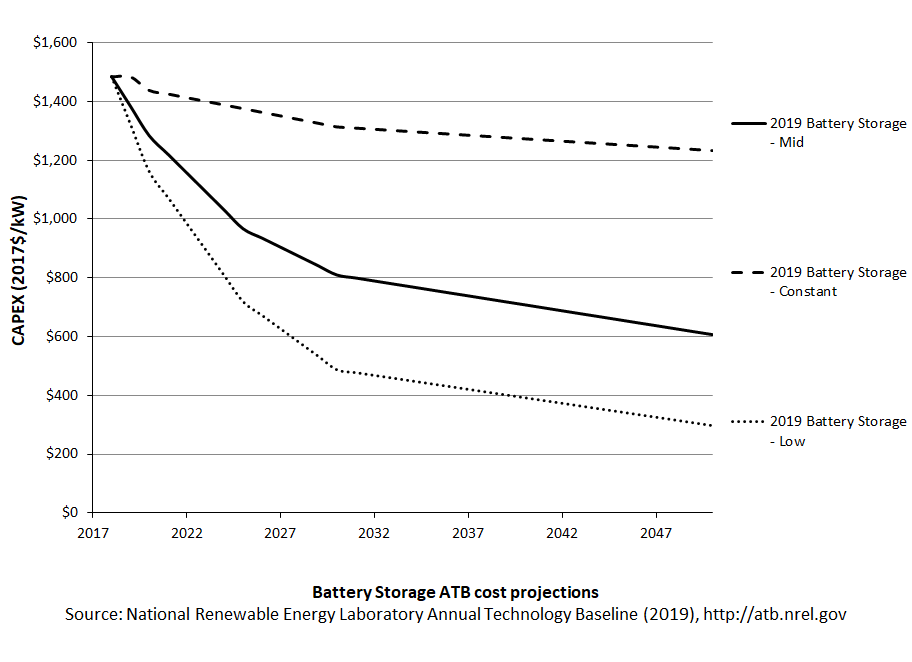

Battery cost and performance projections are based on a literature review of 25 sources published between 2016 and 2019, as described by Cole and Frazier (2019) . Three different projections from 2017 to 2050 were developed for scenario modeling based on this literature:

- High Technology Cost Scenario: generally based on the maximum of literature projections of future CAPEX and O&M technology pathway analysis; distinct from the Constant technology cost scenarios used among renewable energy technologies in the ATB

- Mid Technology Cost Scenario: generally based on the median of literature projections of future CAPEX and O&M technology pathway analysis

- Low Technology Cost Scenario: generally based on the low bound of literature projections of future CAPEX and O&M technology pathway analysis.

Standard Scenarios Model Results

ATB CAPEX, O&M, and round-trip efficiency assumptions for the Base Year and future projections through 2050 for High, Mid, and Low technology cost scenarios are used to develop the NREL Standard Scenarios using the ReEDS model. See ATB and Standard Scenarios.

Representative Technology

The representative technology was a utility-scale lithium-ion battery storage system with a 15-year life and a 4-hour rating, meaning it could discharge at its rated capacity for four hours as described by Cole and Frazier (2019) . Within the ATB spreadsheet, the costs are separated into energy and power cost estimates, which allow capital costs to be constructed for durations other than 4 hours according to the following equation:

For more information on the power vs. energy cost breakdown, see Cole and Frazier (2019) .

Capital Expenditures (CAPEX): Historical Trends, Current Estimates, and Future Projections

Recent Trends

Costs of lithium-ion battery storage systems have declined rapidly in recent years, prompting greater interest in utility-scale applications.

Base Year Estimates

The Base Year cost estimate is taken from Fu, Remo, and Margolis (2018). Comparisons to other reported costs for 2018 are included in Cole, Wesley & Frazier, A. Will (2019). Although the ATB uses a 2017 Base Year, the 2018 estimate based on the literature is the first year reported in the ATB, with a value of $1,484/kW in 2017 dollars.

Future Projections

Future projections are taken from Cole and Frazier (2019), which generally used the median of published cost estimates to develop a Mid Technology Cost Scenario and the minimum values to develop a Low Technology Cost Scenario. Analysts' judgment was used to select the long-term projections to 2050 from a sparse data set.

CAPEX Definition

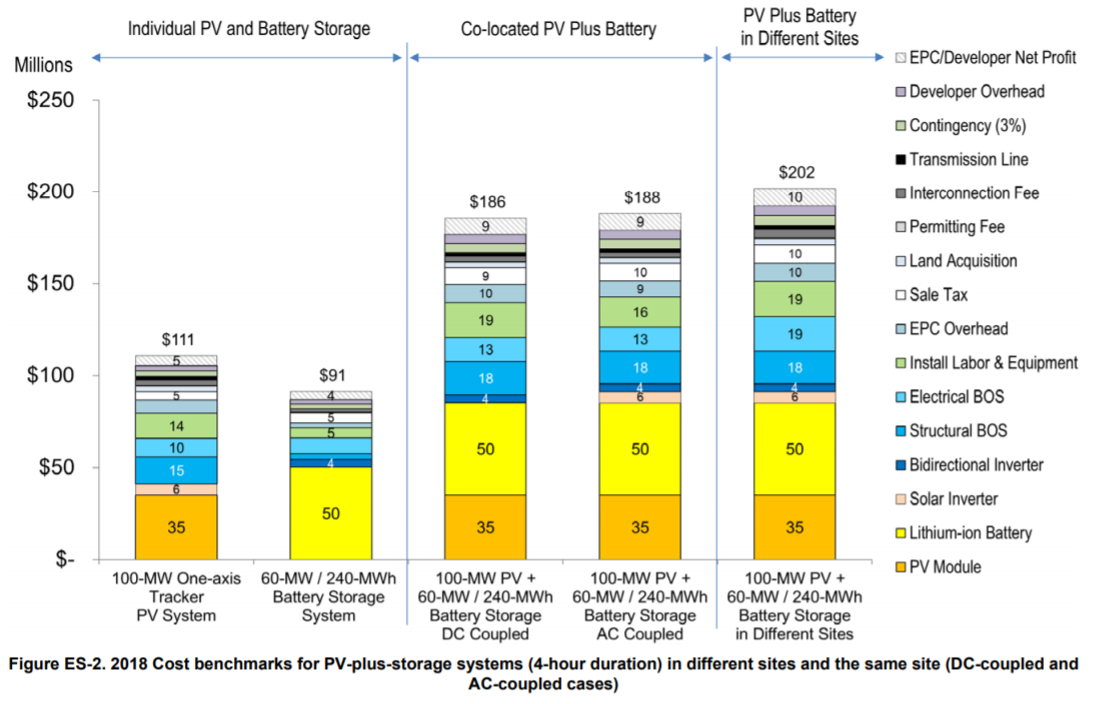

The literature review does not enumerate elements of the capital cost of lithium-ion batteries (Cole, Wesley & Frazier, A. Will, 2019). However, the NREL storage cost report does detail a breakdown of capital costs with the actual battery pack being the largest component but significant other costs are also included. This breakdown is different if the battery is part of a hybrid system with solar PV. These relative costs for utility-scale standalone battery and battery + PV are demonstrated in the figure below (Fu, Remo, & Margolis, 2018).

Operation and Maintenance (O&M) Costs

Base Year Estimates

Cole and Frazier (2019) assumed no variable operation and maintenance (VOM) cost. All operating costs were instead represented using fixed operation and maintenance (FOM) costs. The FOM costs include augmentation costs needed to keep the battery system operating at rated capacity for its lifetime. In the ATB, FOM is defined as the value needed to compensate for degradation to enable the battery system to have a constant capacity throughout its life. The literature review states that FOM costs are estimated at 2.5% of the $/kW capital costs.

Future Projections

In the ATB, the FOM cost remains constant at 2.5% of capital costs in all scenarios.

Round-trip efficiency is the ratio of useful energy output to useful energy input. Cole and Frazier (2019) identified 85% as a representative round-trip efficiency, and the ATB adopts this value.

Natural Gas Plants

The ATB includes three natural gas power plant types: a natural gas combustion turbine (gas-CT) and a natural gas combined cycle system (gas-CC) and a natural gas combined cycled system with carbon capture and storage (gas-CC-CCS). The cost and performance characteristics of these plants are adapted from EIA data rather than derived from original analysis.

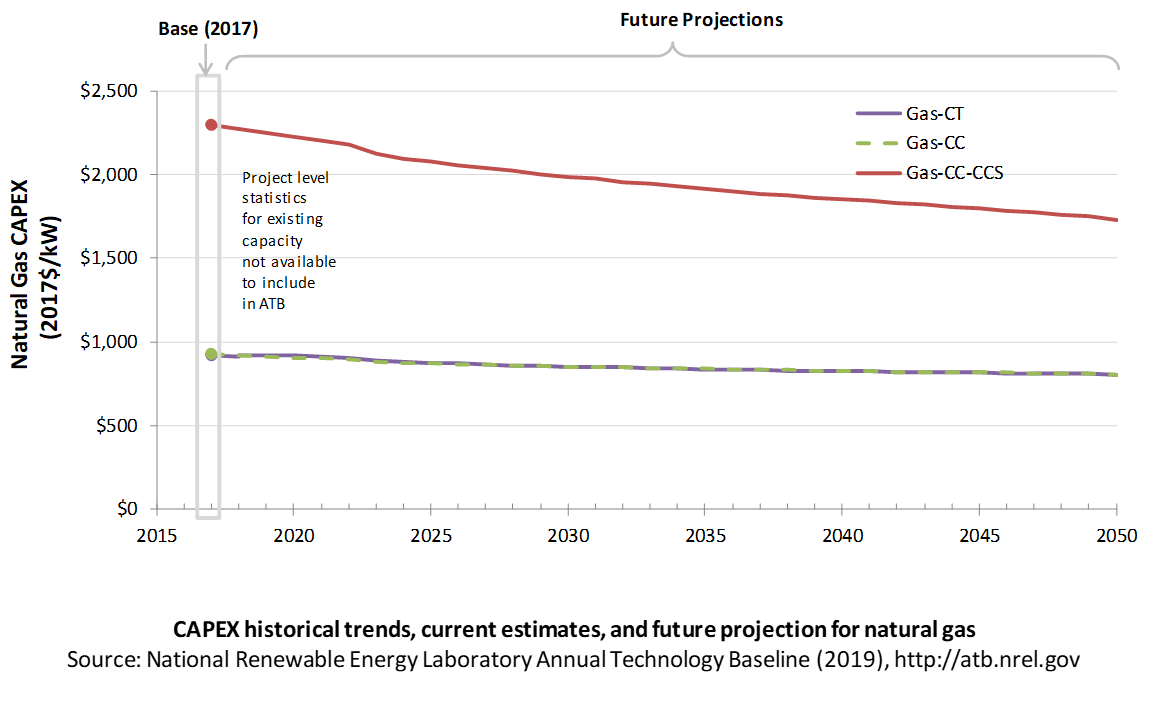

Natural gas plant CAPEX is taken from the AEO2019 (EIA, 2019a) with the adjustments discussed in the CAPEX definition section. The ATB includes only a single CAPEX projection for each type of natural gas plant.

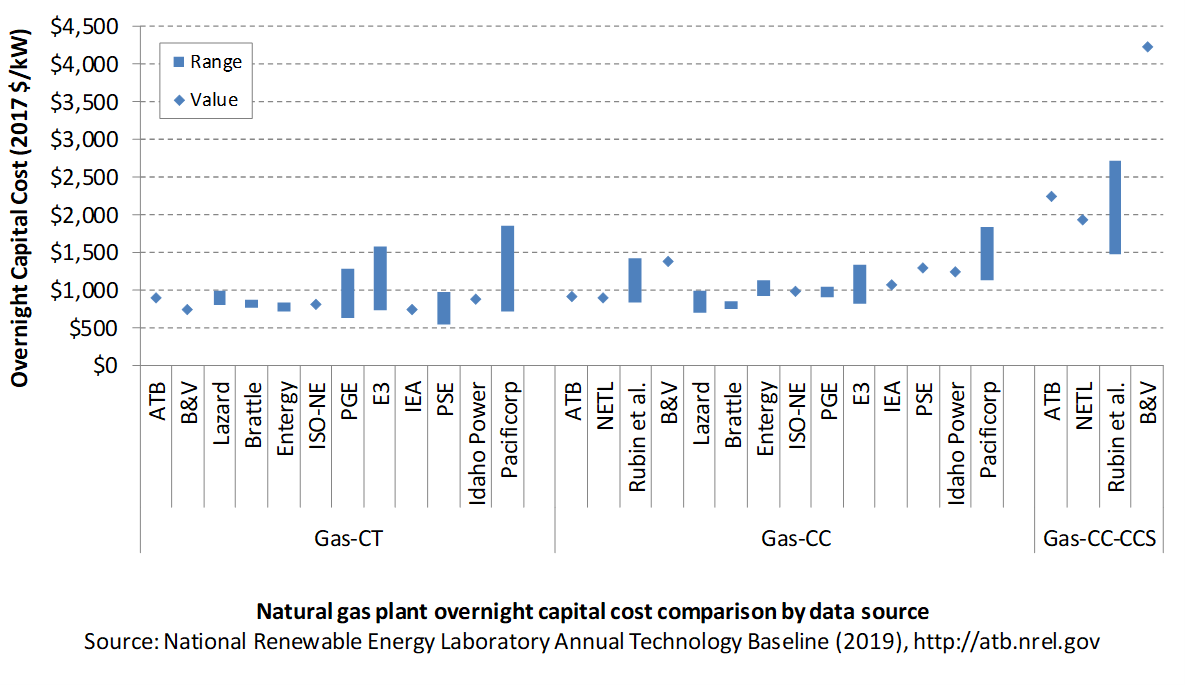

Comparison with Other Sources

Costs vary due to differences in configuration (e.g., 2x1 versus 1x1), turbine class, and methodology. All costs were converted to the same dollar year.

CAPEX Definition

Capital expenditures (CAPEX) are expenditures required to achieve commercial operation in a given year.

Overnight capital costs are modified from Table 123 of the AEO2019 Reference scenario (EIA, 2019a).

EIA reports two types of gas-CT and gas-CC technologies in EIA's Annual Energy Outlook: advanced (H-class for gas-CC, F-class for gas-CT) and conventional (F-class for gas-CC, LM-6000 for gas-CT). Because we represent a single gas-CT and gas-CC technology in the ATB, the characteristics for the ATB plants are taken to be the average of the advanced and conventional systems as reported by EIA. For example, the overnight capital cost for the gas-CC technology in the ATB is the average of the capital cost of the advanced and conventional combined cycle technologies from the Annual Energy Outlook. The EIA only has a single advanced technology for gas-CC-CCS, which we use as the basis for that plant type in the ATB. The CCS plant configuration includes only the cost of capturing and compressing the CO2. It does not include CO2 delivery and storage.

The EIA projections were further adjusted by removing the material price index. The material price index accounts for projected changes in the price index for metals and metals products, and it is independent of the learning-based cost reductions applied in the EIA projections.

| Overnight Capital Cost ($/kW) | Construction Financing Factor (ConFinFactor) | CAPEX ($/kW) | |

| Gas-CT: National-gas-fired combustion turbine | $899 | 1.022 | $919 |

| Gas-CC: National-gas-fired combined cycle | $906 | 1.022 | $927 |

| Gas-CC-CCS: Combined cycle with carbon capture sequestration | $2,242 | 1.022 | $2,292 |

CAPEX can be determined for a plant in a specific geographic location as follows:

Regional cost variations and geographically specific grid connection costs are not included in the ATB (CapRegMult = 1; GCC = 0). In the ATB, the input value is overnight capital cost (OCC) and details to calculate interest during construction (ConFinFactor).

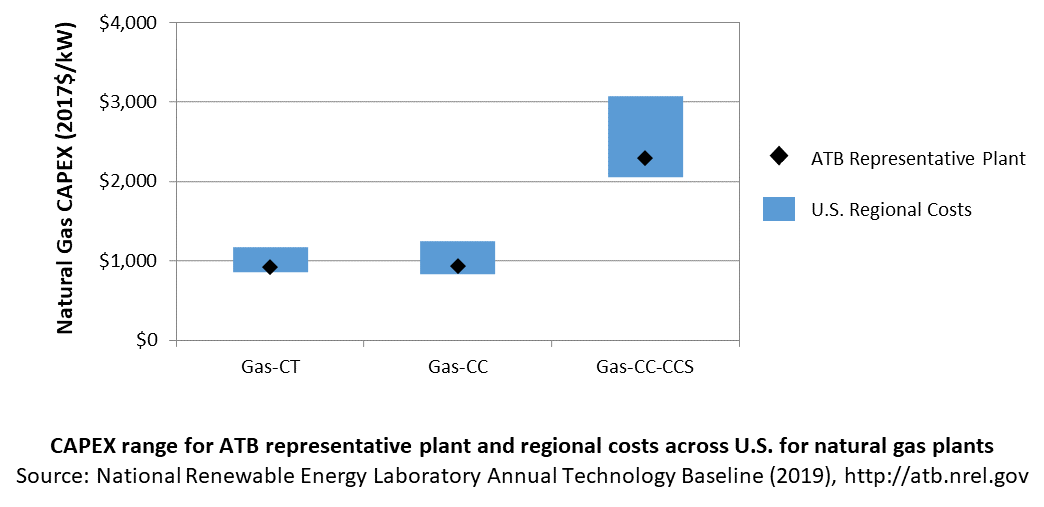

In the ATB, CAPEX represents each type of gas plant with a unique value. Regional cost effects associated with labor rates, material costs, and other regional effects as defined by (EIA, 2016) expand the range of CAPEX. Unique land-based spur line costs based on distance and transmission line costs are not estimated. The following figure illustrates the ATB representative plant relative to the range of CAPEX including regional costs across the contiguous United States. The ATB representative plants are associated with a regional multiplier of 1.0.

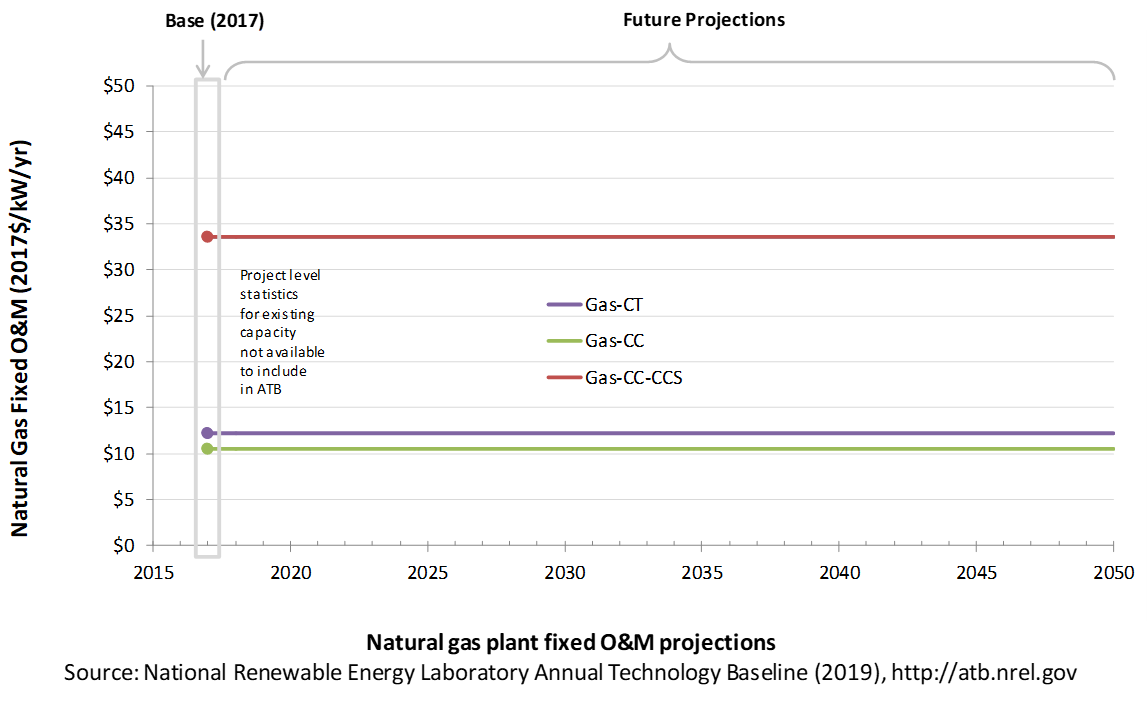

Operation and Maintenance (O&M) Costs

Natural gas plant fixed and variable O&M costs are taken from table 8.2 of the AEO2019, and they are assumed to be constant over time.

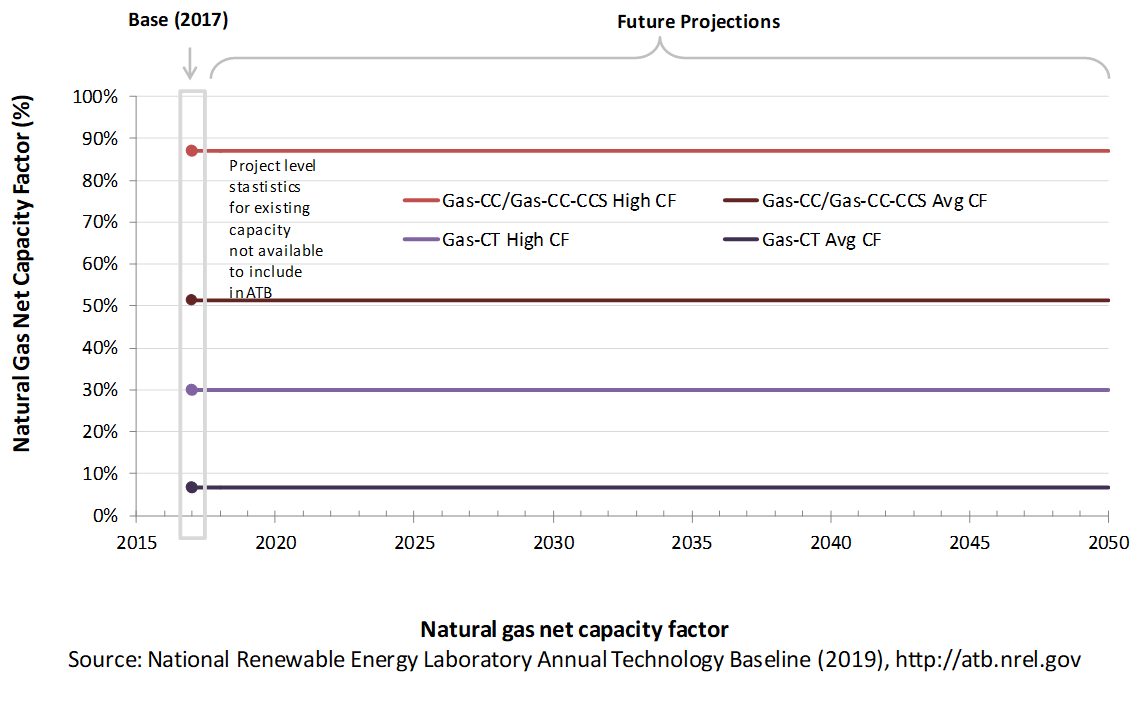

Capacity Factor: Expected Annual Average Energy Production Over Lifetime

The capacity factor represents the assumed annual energy production divided by the total possible annual energy production, assuming the plant operates at rated capacity for every hour of the year. For natural gas plants, the capacity factor is typically lower (and, in the case of combustion turbines, much lower) than their availability factor. Natural gas plants have availability factors approaching 100%.

The capacity factors of dispatchable units is typically a function of the unit's marginal costs and local grid needs (e.g., need for voltage support or limits due to transmission congestion). The average capacity factor is the average fleet-wide capacity factor for these plant types in 2017. The high capacity factor is taken from Table 1a of (EIA, 2019a) for a new power plant and represents a high bound of operation for a plant of this type.

Gas-CT power plants are less efficient than gas-CC power plants, and they tend to run as intermediate or peaker plants.

Gas-CC with CCS has not yet been built, but when built it is expected to operate as a baseload unit.

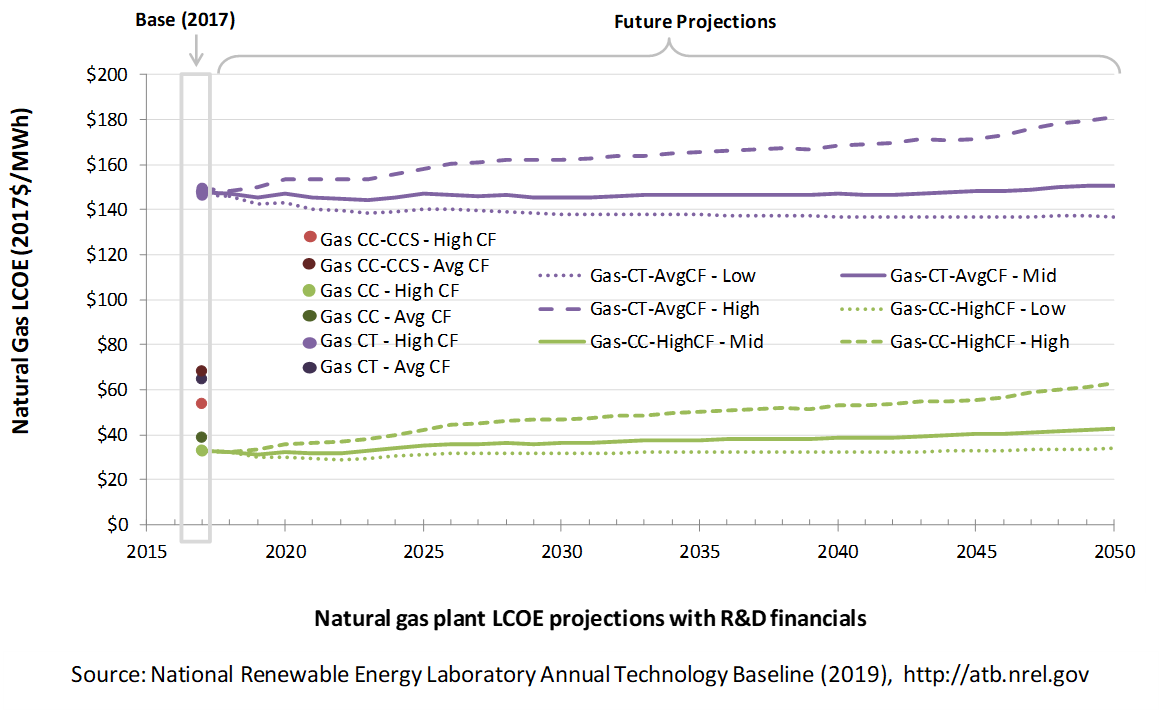

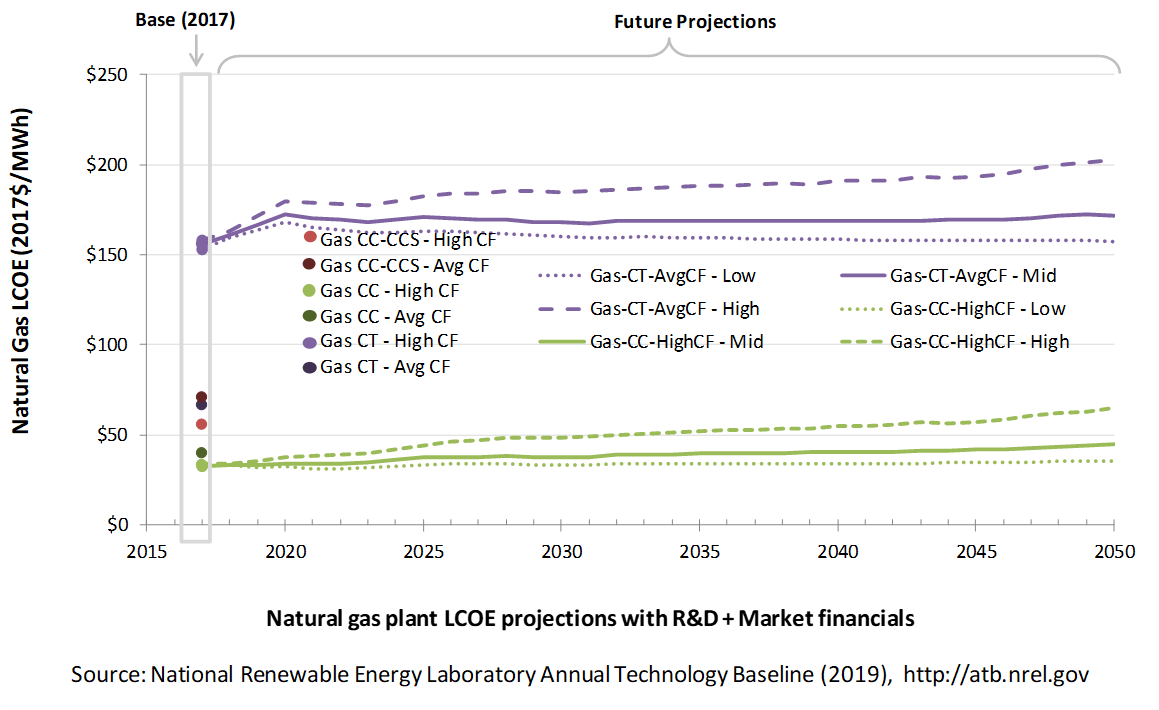

Levelized Cost of Energy (LCOE) Projections

Levelized cost of energy (LCOE) is a summary metric that combines the primary technology cost and performance parameters: CAPEX, O&M, and capacity factor. It is included in the ATB for illustrative purposes. The ATB focuses on defining the primary cost and performance parameters for use in electric sector modeling or other analysis where more sophisticated comparisons among technologies are made. The LCOE accounts for the energy component of electric system planning and operation. The LCOE uses an annual average capacity factor when spreading costs over the anticipated energy generation. This annual capacity factor ignores specific operating behavior such as ramping, start-up, and shutdown that could be relevant for more detailed evaluations of generator cost and value. Electricity generation technologies have different capabilities to provide such services. For example, wind and PV are primarily energy service providers, while the other electricity generation technologies provide capacity and flexibility services in addition to energy. These capacity and flexibility services are difficult to value and depend strongly on the system in which a new generation plant is introduced. These services are represented in electric sector models such as the ReEDS model and corresponding analysis results such as the Standard Scenarios.

The following three figures illustrate LCOE, which includes the combined impact of CAPEX, O&M, fuel prices, and capacity factor projections for natural gas in the contiguous United States. For the purposes of the ATB, the costs associated with technology and project risk in the U.S. market are represented in the financing costs but not in the upfront capital costs (e.g., developer fees and contingencies). An individual technology may receive more favorable financing terms outside the United States, due to less technology and project risk, caused by more project development experience (e.g., offshore wind in Europe) or more government or market guarantees. The R&D Only LCOE sensitivity cases present the range of LCOE based on financial conditions that are held constant over time unless R&D affects them, and they reflect different levels of technology risk. This case excludes effects of tax reform, tax credits, and changing interest rates over time. The R&D + Market LCOE case adds to these financial assumptions: (1) the changes over time consistent with projections in the Annual Energy Outlook and (2) the effects of tax reform and tax credits (the 45Q tax credits are not included in this year's ATB). The ATB representative plant characteristics that best align with those of recently installed or anticipated near-term natural gas plants are associated with Gas-CC-HighCF. Data for all the resource categories can be found in the ATB Data spreadsheet; for simplicity, not all resource categories are shown in the figures; for simplicity, not all resource categories are shown in the figures. Variations in LCOE among the low, mid, and high projections for natural gas plants are driven by fuel price differences only.

R&D Only | R&D + Market

The LCOE of natural gas plants is directly impacted by the price of the natural gas fuel, so we include low, mid, and high natural gas price trajectories. The LCOE is also impacted by variations in the heat rate and O&M costs. Because the reference and high natural gas price projections from AEO2019 (EIA, 2019a) are rising over time, the LCOE of new natural gas plants can increase over time if the gas prices rise faster than the capital costs decline. For a given year, the LCOE assumes that the fuel prices from that year continue throughout the lifetime of the plant.

These projections do not include any cost of carbon, which would influence the LCOE of fossil units. Also, for CCS plants, the potential revenue from selling the captured carbon is not included (e.g., enhanced oil recovery operations may purchase CO2 from a CCS plant).

Fuel prices are based on the AEO2019.

LCOE is sensitive to assumptions about the financing of electricity generation projects. Two project finance structures are used within the ATB:

- R&D Only Financial Assumptions: This sensitivity case allows technology-specific changes to debt interest rates, return on equity rates, and debt fraction to reflect effects of R&D on technological risk perception, but it holds background rates constant at 2017 values from AEO2019 (EIA, 2019a) and excludes effects of tax reform and tax credits. A constant cost recovery period-or period over which the initial capital investment is recovered-of 30 years is assumed for all technologies.

- R&D Only + Market Financial Assumptions: This sensitivity case retains the technology-specific changes to debt interest, return on equity rates, and debt fraction from the R&D Only case and adds in the variation over time consistent with AEO2019 (EIA, 2019a) as well as effects of tax reform and tax credits. As in the R&D Only case, a constant cost recovery period-or period over which the initial capital investment is recovered-of 30 years is assumed for all technologies. For a detailed discussion of these assumptions, see Project Finance Impact on LCOE.

A constant cost recovery period-over which the initial capital investment is recovered-is assumed for all technologies throughout this website and can be varied in the ATB Data spreadsheet.

The equations and variables used to estimate LCOE are defined on the Equations and Variables page. For illustration of the impact of changing financial structures such as WACC, see Project Finance Impact on LCOE. For LCOE estimates for the Constant, Mid, and Low technology cost scenarios for all technologies, see 2019 ATB Cost and Performance Summary.

Nuclear

The ATB includes a single nuclear power plant type. The cost and performance of this plant type is adapted from EIA data rather than derived from original analysis.

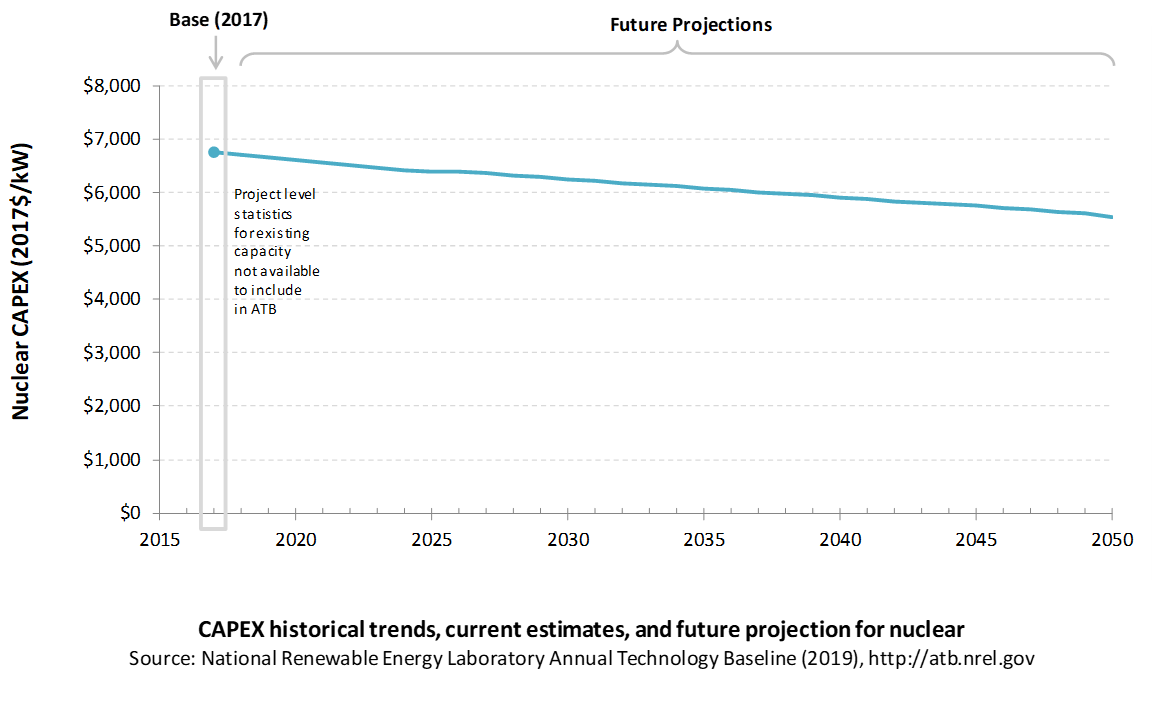

Capital Expenditures (CAPEX): Historical Trends, Current Estimates, and Future Projections

Nuclear power plant CAPEX is taken from the AEO2019 Reference Scenario (EIA, 2019a) with the adjustments discussed in the CAPEX definition section. The EIA advanced nuclear option is based on two AP1000 nuclear power plant units built on a brownfield site. The ATB includes only a single CAPEX projection for nuclear plants.

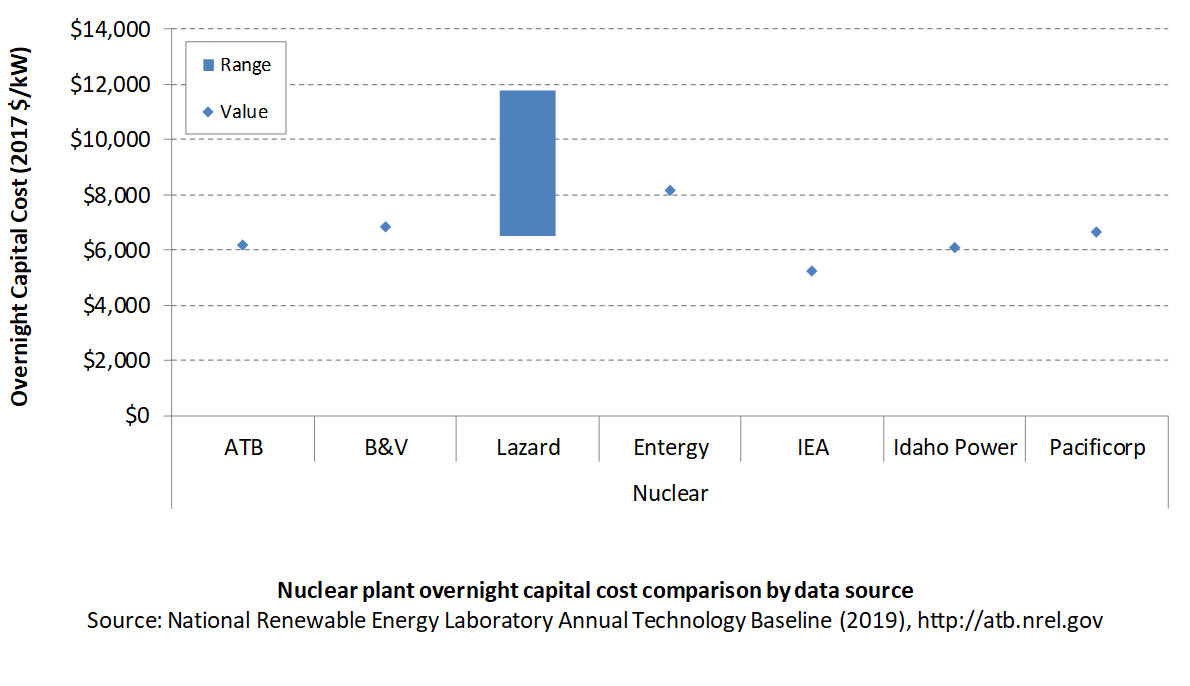

Comparison with Other Sources

CAPEX Definition

Capital expenditures (CAPEX) are expenditures required to achieve commercial operation in a given year.

Overnight capital costs are modified from AEO2019 (EIA, 2019a). The EIA projections were adjusted by removing the material price index. The material price index accounts for projected changes in the price index for metals and metals products, and it is independent of the learning-based cost reductions applied in the EIA projections.

| Overnight Capital Cost ($/kW) | Construction Financing Factor (ConFinFactor) | CAPEX ($/kW) | |

| Nuclear: Advanced nuclear power generation | $6,200 | 1.087 | $6,742 |

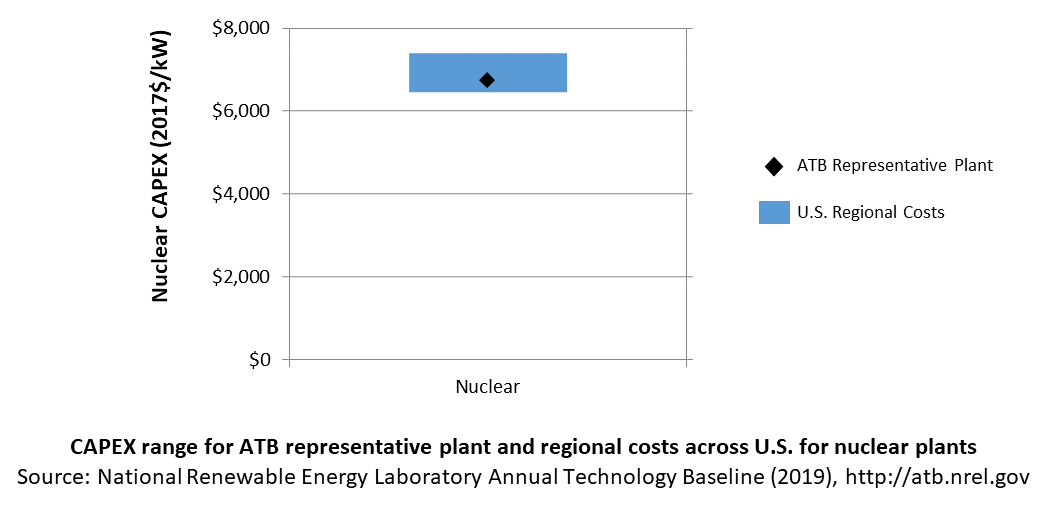

CAPEX can be determined for a plant in a specific geographic location as follows:

Regional cost variations and geographically specific grid connection costs are not included in the ATB (CapRegMult = 1; GCC = 0). In the ATB, the input value is overnight capital cost (OCC) and details to calculate interest during construction (ConFinFactor).

In the ATB, CAPEX represents each type of nuclear plant with a unique value. Regional cost effects associated with labor rates, material costs, and other regional effects as defined by (EIA, 2016) expand the range of CAPEX (Plant × Region). Unique land-based spur line costs based on distance and transmission line costs are not estimated. The following figure illustrates the ATB representative plant relative to the range of CAPEX including regional costs across the contiguous United States. The ATB representative plants are associated with a regional multiplier of 1.0.

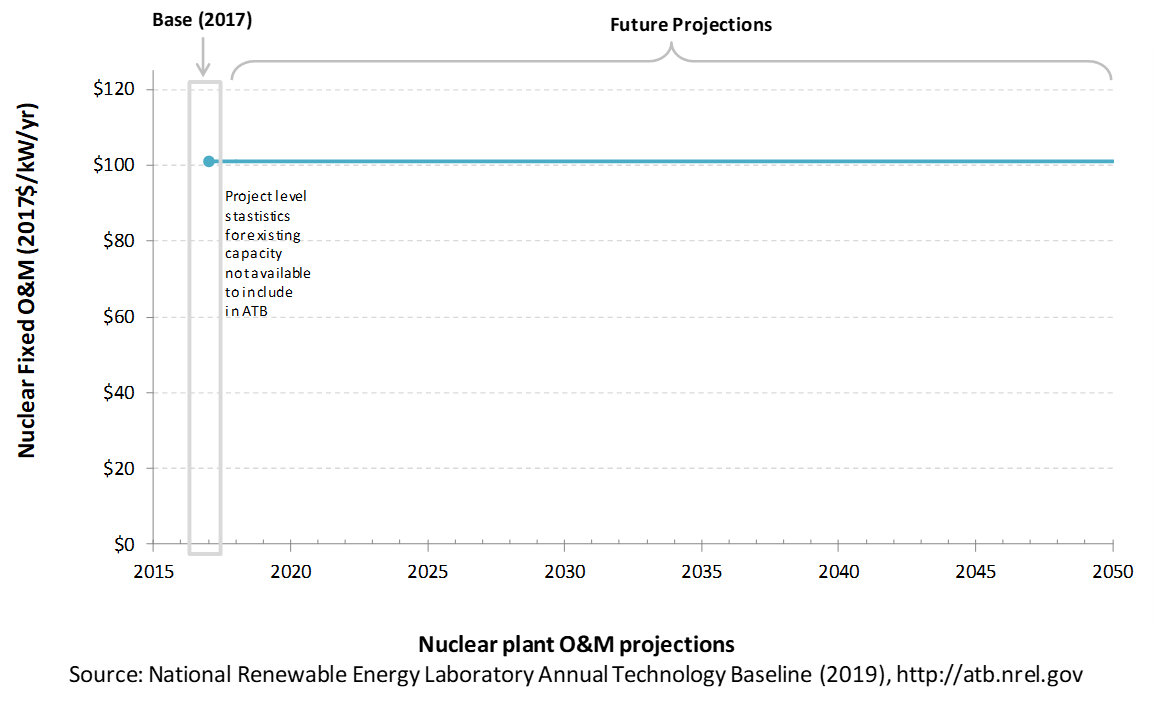

Operation and Maintenance (O&M) Costs

Nuclear power plant fixed and variable O&M costs are taken from table 8.2 of the AEO2019, and they are assumed to be constant over time.

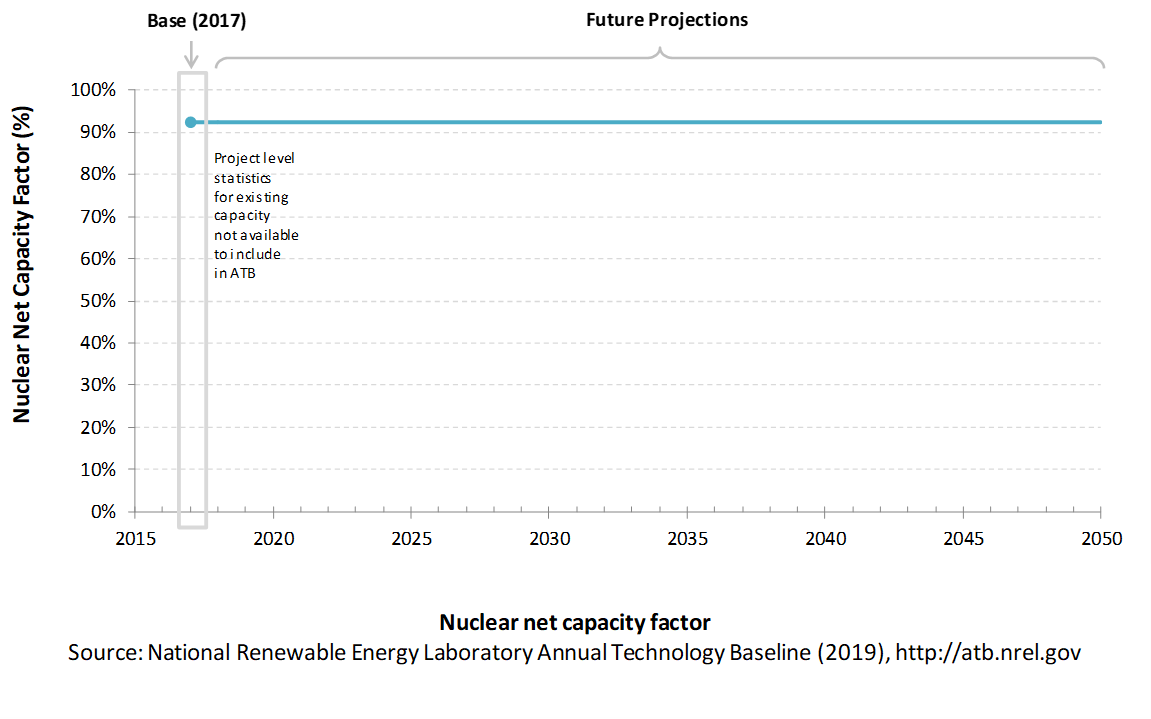

Capacity Factor: Expected Annual Average Energy Production Over Lifetime

The capacity factor represents the assumed annual energy production divided by the total possible annual energy production, assuming the plant operates at rated capacity for every hour of the year. For nuclear plants, the capacity factor is typically the same as (or very close to) their availability factor. For the ATB we assign the nuclear capacity factor as the fleet-wide average from 2017.

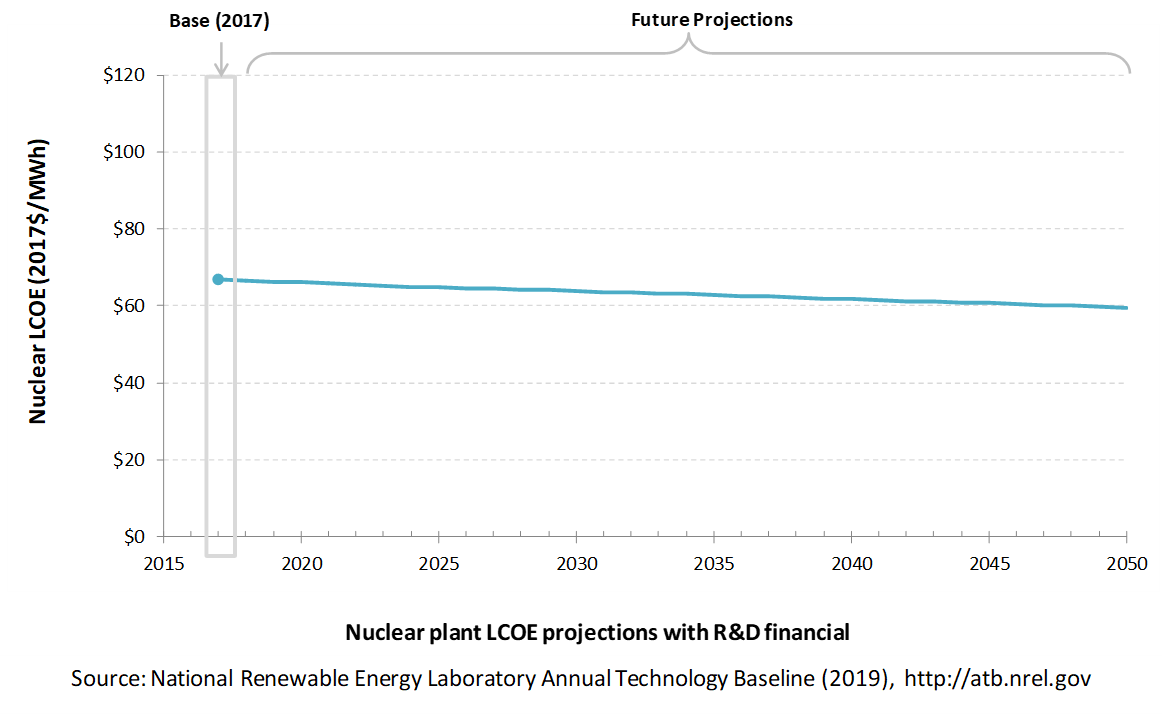

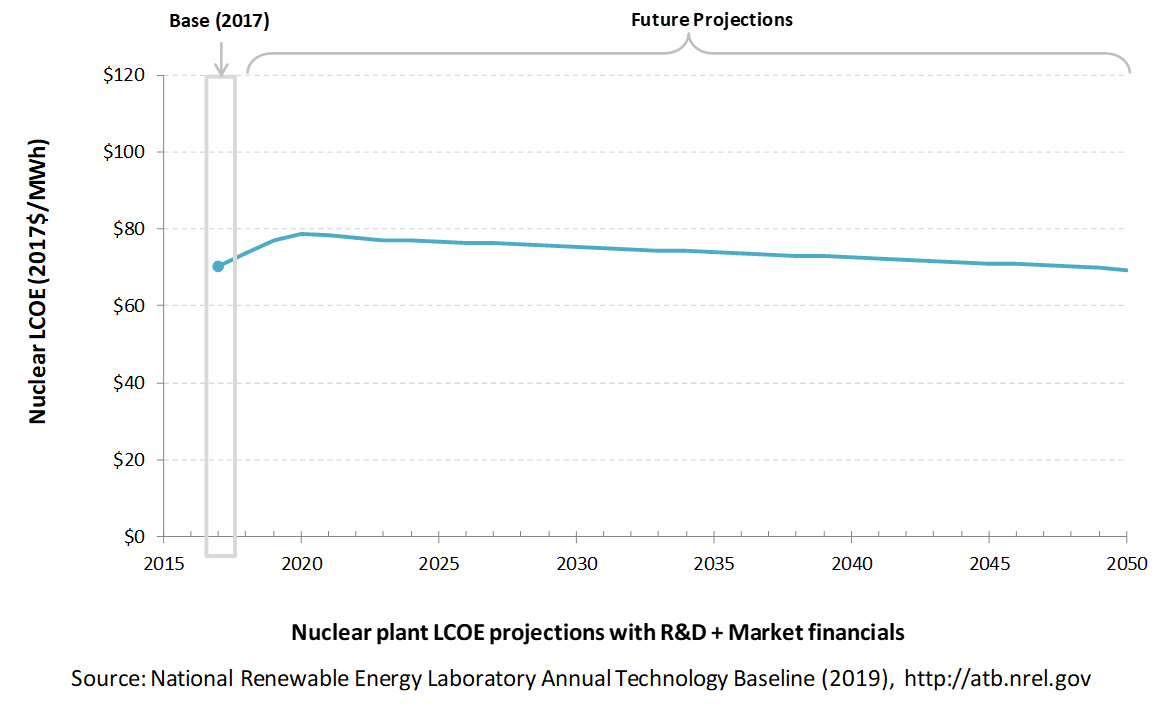

Levelized Cost of Energy (LCOE) Projections

Levelized cost of energy (LCOE) is a summary metric that combines the primary technology cost and performance parameters: CAPEX, O&M, and capacity factor. It is included in the ATB for illustrative purposes. The ATB focuses on defining the primary cost and performance parameters for use in electric sector modeling or other analysis where more sophisticated comparisons among technologies are made. The LCOE accounts for the energy component of electric system planning and operation. The LCOE uses an annual average capacity factor when spreading costs over the anticipated energy generation. This annual capacity factor ignores specific operating behavior such as ramping, start-up, and shutdown that could be relevant for more detailed evaluations of generator cost and value. Electricity generation technologies have different capabilities to provide such services. For example, wind and PV are primarily energy service providers, while the other electricity generation technologies provide capacity and flexibility services in addition to energy. These capacity and flexibility services are difficult to value and depend strongly on the system in which a new generation plant is introduced. These services are represented in electric sector models such as the ReEDS model and corresponding analysis results such as the Standard Scenarios.

The following three figures illustrate LCOE, which includes the combined impact of CAPEX, O&M, and capacity factor projections for nuclear across the range of resources present in the contiguous United States. For the purposes of the ATB, the costs associated with technology and project risk in the U.S. market are represented in the financing costs but not in the upfront capital costs (e.g., developer fees and contingencies). An individual technology may receive more favorable financing terms outside the United States, due to less technology and project risk, caused by more project development experience (e.g., offshore wind in Europe) or more government or market guarantees. The R&D Only LCOE sensitivity cases present the range of LCOE based on financial conditions that are held constant over time unless R&D affects them, and they reflect different levels of technology risk. This case excludes effects of tax reform, tax credits, and changing interest rates over time. The R&D + Market LCOE case adds to these financial assumptions: (1) the changes over time consistent with projections in the Annual Energy Outlook and (2) the effects of tax reform and tax credits.

R&D Only | R&D + Market

The LCOE of nuclear power plants is directly impacted by the cost of uranium, variations in the heat rate, and O&M costs, but the biggest factor is the capital cost (including financing costs) of the plant. The LCOE can also be impacted by the amount of downtime from refueling or maintenance. For a given year, the LCOE assumes that the fuel prices from that year continue throughout the lifetime of the plant.

Fuel prices are based on the AEO2019 (EIA, 2019a).

To estimate LCOE, assumptions about the cost of capital to finance electricity generation projects are required, and the LCOE calculations are sensitive to these financial assumptions. Two project finance structures are used within the ATB:

- R&D Only Financial Assumptions: This sensitivity case allows technology-specific changes to debt interest rates, return on equity rates, and debt fraction to reflect effects of R&D on technological risk perception, but it holds background rates constant at 2017 values from AEO2019 (EIA, 2019a) and excludes effects of tax reform and tax credits. A constant cost recovery period-or period over which the initial capital investment is recovered-of 30 years is assumed for all technologies.

- R&D Only + Market Financial Assumptions: This sensitivity case retains the technology-specific changes to debt interest, return on equity rates, and debt fraction from the R&D Only case and adds in the variation over time consistent with AEO2019 (EIA, 2019a) as well as effects of tax reform and tax credits. As in the R&D Only case, a constant cost recovery period-or period over which the initial capital investment is recovered-of 30 years is assumed for all technologies. For a detailed discussion of these assumptions, see Project Finance Impact on LCOE.

The equations and variables used to estimate LCOE are defined on the Equations and Variables page. For illustration of the impact of changing financial structures such as WACC, see Project Finance Impact on LCOE. For LCOE estimates for the Constant, Mid, and Low technology cost scenarios for all technologies, see 2019 ATB Cost and Performance Summary.

Biopower

The ATB includes both dedicated biopower cost options and a biomass cofired with coal option. The cost and performance characteristics of these plants are adapted from EIA data rather than derived from original analysis.

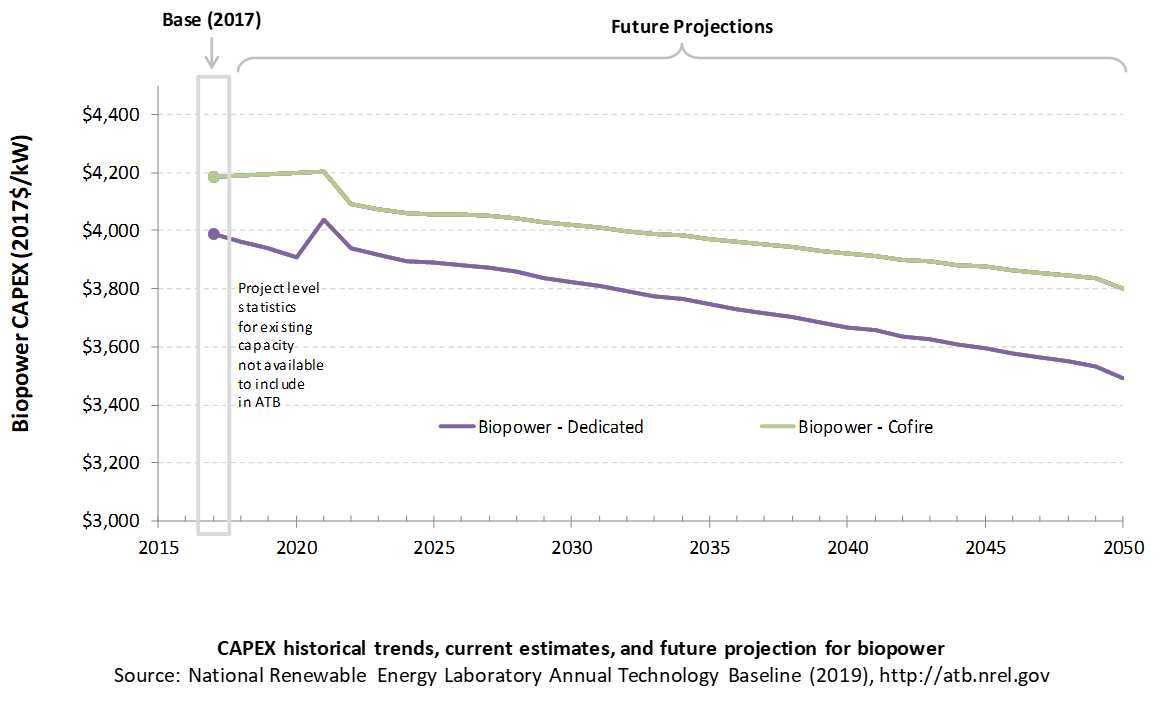

Capital Expenditures (CAPEX): Historical Trends, Current Estimates, and Future Projections

Biopower plant CAPEX is taken from the AEO2019 Reference Scenario (EIA, 2019a) with the adjustments discussed in the CAPEX definition section.

CAPEX Definition

Capital expenditures (CAPEX) are expenditures required to achieve commercial operation in a given year.

Overnight capital costs are modified from AEO2019 (EIA, 2019a). The EIA projections were adjusted by removing the material price index. The material price index accounts for projected changes in the price index for metals and metals products, and it is independent of the learning-based cost reductions applied in the EIA projections.

Fuel costs are taken from the Billion Ton Update study (DOE et al., 2011).

| Overnight Capital Cost ($/kW) | Construction Financing Factor (ConFinFactor) | CAPEX ($/kW) | |

| Dedicated: Dedicated biopower plant | $3,827 | 1.042 | $3,990 |

| CofireOld: Pulverized coal with sulfur dioxide (SO2) scrubbers and biomass co-firing | $4,013 | 1.042 | $4,184 |

| CofireNew: Advanced supercritical coal with SO2 and NOx controls and biomass co-firing | $4,013 | 1.042 | $4,184 |

CAPEX can be determined for a plant in a specific geographic location as follows:

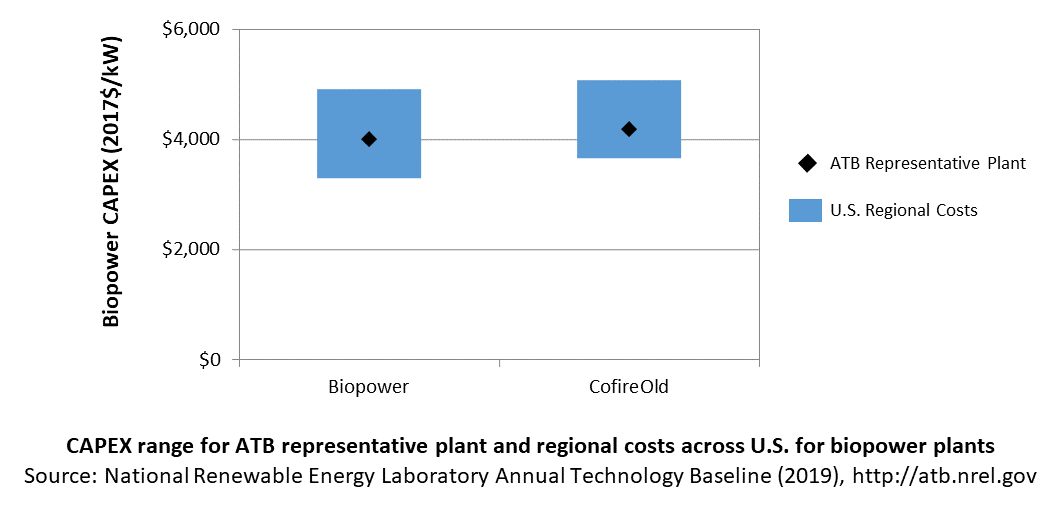

Regional cost variations and geographically specific grid connection costs are not included in the ATB (CapRegMult = 1; GCC = 0). In the ATB, the input value is overnight capital cost (OCC) and details to calculate interest during construction (ConFinFactor).

In the ATB, CAPEX represents each type of biopower plant with a unique value. Regional cost effects associated with labor rates, material costs, and other regional effects as defined by (EIA, 2016) expand the range of CAPEX. Unique land-based spur line costs based on distance and transmission line costs are not estimated. The following figure illustrates the ATB representative plant relative to the range of CAPEX including regional costs across the contiguous United States. The ATB representative plants are associated with a regional multiplier of 1.0.

Operation and Maintenance (O&M) Costs

Biopower power plant fixed and variable O&M costs are taken from table 8.2 of the AEO2019, and they are assumed to be constant over time.

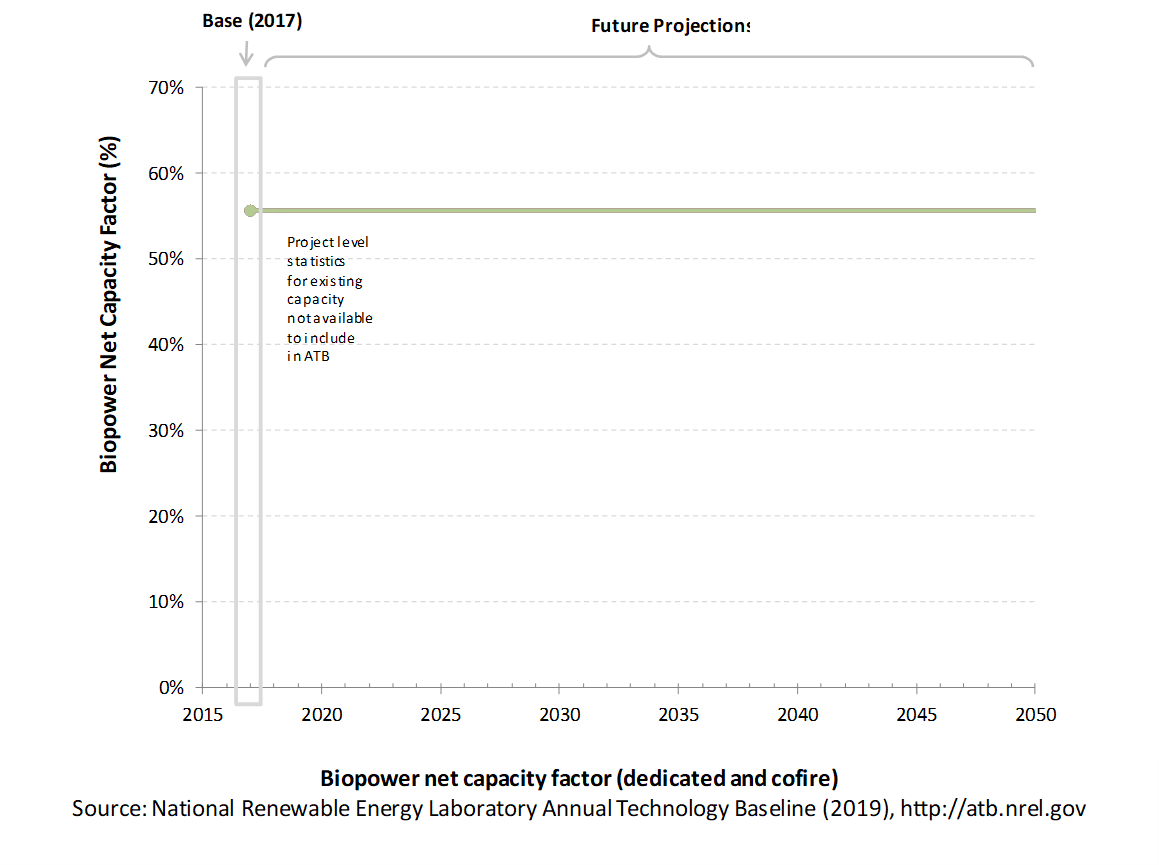

Capacity Factor: Expected Annual Average Energy Production Over Lifetime

The capacity factor represents the assumed annual energy production divided by the total possible annual energy production, assuming the plant operates at rated capacity for every hour of the year. For biopower plants, the capacity factors are typically lower than their availability factors. Biopower plant availability factors have a wide range depending on system design, fuel type and availability, and maintenance schedules.

Biopower plants are typically baseload plants with steady capacity factors. For the ATB, the biopower capacity factor is taken as the average capacity factor for biomass plants for 2017, as reported by EIA.

Biopower capacity factors are influenced by technology and feedstock supply, expected downtime, and energy losses.

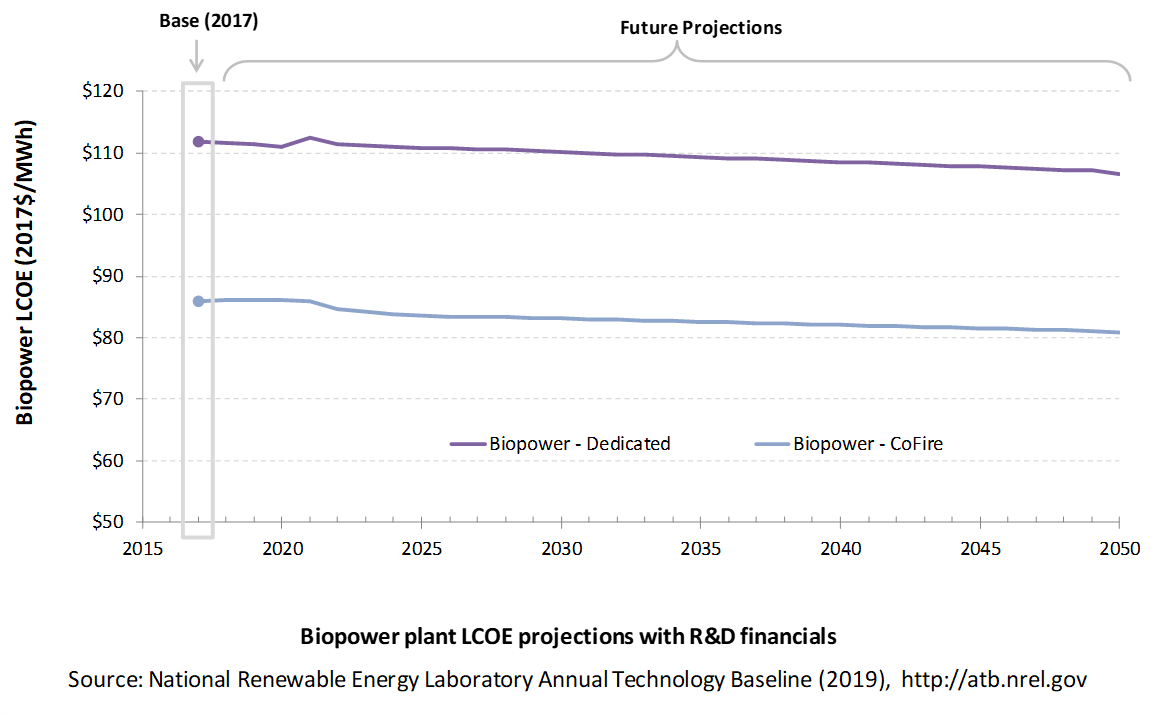

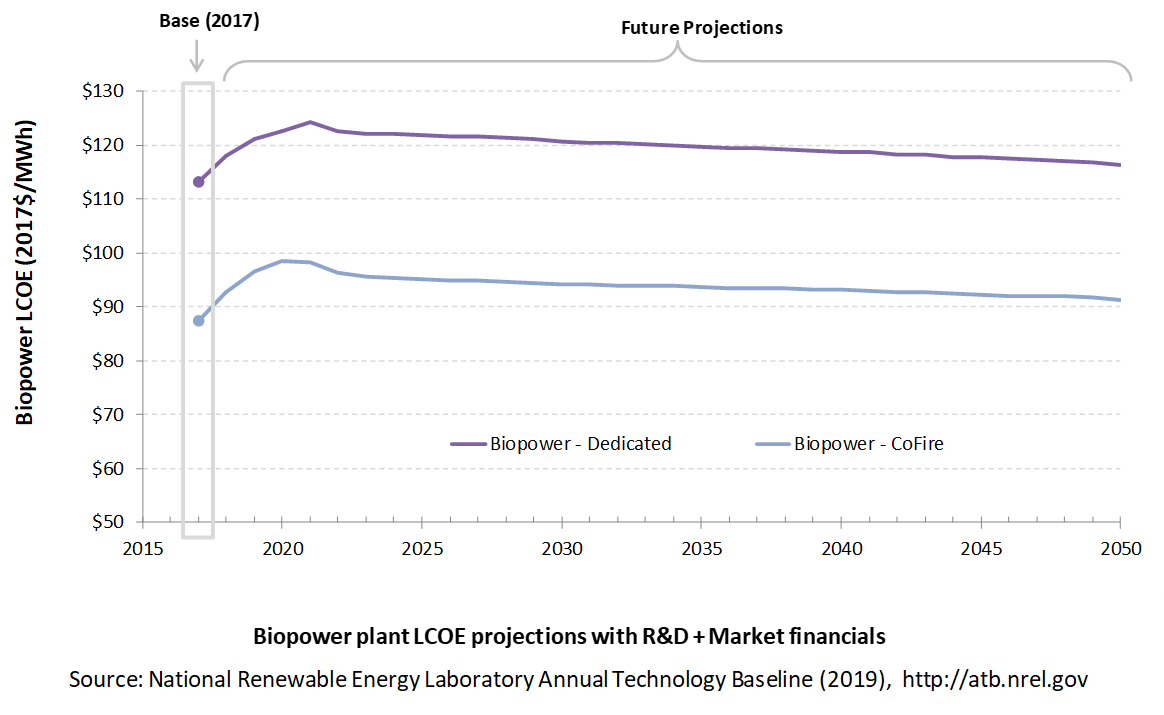

Levelized Cost of Energy (LCOE) Projections

Levelized cost of energy (LCOE) is a summary metric that combines the primary technology cost and performance parameters: CAPEX, O&M, and capacity factor. It is included in the ATB for illustrative purposes. The ATB focuses on defining the primary cost and performance parameters for use in electric sector modeling or other analysis where more sophisticated comparisons among technologies are made. The LCOE accounts for the energy component of electric system planning and operation. The LCOE uses an annual average capacity factor when spreading costs over the anticipated energy generation. This annual capacity factor ignores specific operating behavior such as ramping, start-up, and shutdown that could be relevant for more detailed evaluations of generator cost and value. Electricity generation technologies have different capabilities to provide such services. For example, wind and PV are primarily energy service providers, while the other electricity generation technologies provide capacity and flexibility services in addition to energy. These capacity and flexibility services are difficult to value and depend strongly on the system in which a new generation plant is introduced. These services are represented in electric sector models such as the ReEDS model and corresponding analysis results such as the Standard Scenarios.

The following three figures illustrate LCOE, which includes the combined impact of CAPEX, O&M, and capacity factor projections for biomass across the range of resources present in the contiguous United States. For the purposes of the ATB, the costs associated with technology and project risk in the U.S. market are represented in the financing costs but not in the upfront capital costs (e.g., developer fees and contingencies). An individual technology may receive more favorable financing terms outside the United States, due to less technology and project risk, caused by more project development experience (e.g., offshore wind in Europe) or more government or market guarantees. The R&D Only LCOE sensitivity cases present the range of LCOE based on financial conditions that are held constant over time unless R&D affects them, and they reflect different levels of technology risk. This case excludes effects of tax reform, tax credits, and changing interest rates over time. The R&D + Market LCOE case adds to these financial assumptions: (1) the changes over time consistent with projections in the Annual Energy Outlook and (2) the effects of tax reform and tax credits. Data for all the resource categories can be found in the ATB data spreadsheet; for simplicity, not all resource categories are shown in the figures.

R&D Only | R&D + Market

The LCOE of biopower plants is directly impacted by the differences in CAPEX (installed capacity costs) as well as by heat rate differences. For a given year, the LCOE assumes that the fuel prices from that year continue throughout the lifetime of the plant.

Regional variations will ultimately impact biomass feedstock costs, but these are not included in the ATB.

The projections do not include any cost of carbon.

Fuel costs are taken from the Billion Ton Update study (DOE et al., 2011).

To estimate LCOE, assumptions about the cost of capital to finance electricity generation projects are required, and the LCOE calculations are sensitive to these financial assumptions. Two project finance structures are used within the ATB:

- R&D Only Financial Assumptions: This sensitivity case allows technology-specific changes to debt interest rates, return on equity rates, and debt fraction to reflect effects of R&D on technological risk perception, but it holds background rates constant at 2017 values from AEO2019 (EIA, 2019a) and excludes effects of tax reform and tax credits. A constant cost recovery period-or period over which the initial capital investment is recovered-of 30 years is assumed for all technologies.

- R&D Only + Market Financial Assumptions: This sensitivity case retains the technology-specific changes to debt interest, return on equity rates, and debt fraction from the R&D Only case and adds in the variation over time consistent with AEO2019 (EIA, 2019a) as well as effects of tax reform and tax credits. As in the R&D Only case, a constant cost recovery period-or period over which the initial capital investment is recovered-of 30 years is assumed for all technologies. For a detailed discussion of these assumptions, see Project Finance Impact on LCOE.

The equations and variables used to estimate LCOE are defined on the Equations and Variables page. For illustration of the impact of changing financial structures such as WACC, see Project Finance Impact on LCOE. For LCOE estimates for the Constant, Mid, and Low technology cost scenarios for all technologies, see 2019 ATB Cost and Performance Summary.

References

The following references are specific to this page; for all references in this ATB, see References.Ardani, K., O'Shaughnessy, E., Fu, R., McClurg, C., Huneycutt, J., & Margolis, R. (2017). Installed Cost Benchmarks and Deployment Barriers for Residential Solar Photovoltaics with Energy Storage: Q1 2016 (No. NREL/TP-7A40-67474). Retrieved from National Renewable Energy Laboratory website: Installed Cost Benchmarks and Deployment Barriers for Residential Solar Photovoltaics with Energy Storage: Q1 2016

Black & Veatch. (2012). Cost and Performance Data for Power Generation Technologies. Retrieved from Black & Veatch Corporation website: https://www.bv.com/docs/reports-studies/nrel-cost-report.pdf

Cole, Wesley, & Frazier, A. Will. (2019). Cost Projections for Utility-Scale Battery Storage (No. NREL/TP-6A20-73222). Retrieved from National Renewable Energy Laboratory website: https://www.nrel.gov/docs/fy19osti/73222.pdf

DOE. (2011). U.S. Billion-Ton Update: Biomass Supply for a Bioenergy and Bioproducts Industry (No. ORNL/TM-2011/224). https://doi.org/10.2172/1023318

DOE. (2016). Hydropower Vision: A New Chapter for America's Renewable Electricity Source (No. DOE/GO-102016-4869). Retrieved from U.S. Department of Energy website: https://www.energy.gov/sites/prod/files/2018/02/f49/Hydropower-Vision-021518.pdf

EIA. (2016b). Capital Cost Estimates for Utility Scale Electricity Generating Plants. Retrieved from U.S. Energy Information Administration website: https://www.eia.gov/analysis/studies/powerplants/capitalcost/pdf/capcost_assumption.pdf

EIA. (2019a). Annual Energy Outlook 2019 with Projections to 2050. Retrieved from U.S. Energy Information Administration website: https://www.eia.gov/outlooks/aeo/pdf/AEO2019.pdf

EIA. (2019b, January). Table 6.7.B Capacity Factors for Utility Scale Generators Not Primarily Using Fossil Fuels. Retrieved April 22, 2019, from https://www.eia.gov/electricity/monthly/epm_table_grapher.php?t=epmt_6_07_b

Entergy Arkansas. (2015). 2015 Integrated Resource Plan. Retrieved from Entergy Arkansas, Inc. website: http://entergy-arkansas.com/content/transition_plan/IRP_Materials_Compiled.pdf

Fu, R., Remo, T. W., & Margolis, R. M. (2018). 2018 U.S. Utility-Scale Photovoltaics-Plus-Energy Storage System Costs Benchmark (No. NREL/TP-6A20-71714). https://doi.org/10.2172/1483474

Kao, S.-C., McManamay, R. A., Stewart, K. M., Samu, N. M., Hadjerioua, B., DeNeale, S. T., … Smith, B. T. (2014). New Stream-Reach Development: A Comprehensive Assessment of Hydropower Energy Potential in the United States (No. ORNL/TM-2013/514). https://doi.org/10.2172/1130425

Lazard. (2016). Lazard's Levelized Cost of Energy Analysis: Version 10.0. Retrieved from Lazard website: https://www.lazard.com/media/438038/levelized-cost-of-energy-v100.pdf

Lopez, A., Roberts, B., Heimiller, D., Blair, N., & Porro, G. (2012). U.S. Renewable Energy Technical Potentials: A GIS-Based Analysis (Technical Report No. NREL/TP-6A20-51946). https://doi.org/10.2172/1219777

MWH. (2009). Hydropower Modernization Initiative, Phase I, Needs and Opportunities Evaluation and Ranking (No. Contract No. W9127N-08-D-0003. Task Order 001.). Montgomery Watson Harza.

O'Connor, P. W., Zhang, Q. F. (Katherine), DeNeale, S. T., Chalise, D. R., & Centurion, E. E. (2015). Hydropower Baseline Cost Modeling (No. ORNL/TM-2015/14). https://doi.org/10.2172/1185882

Varro, L., & Ha, J. (2015). Projected Costs of Generating Electricity: 2015 Edition. Retrieved from International Energy Agency website: https://www.iea.org/media/presentations/150831_ProjectedCostsOfGeneratingElectricity_Presentation.pdf